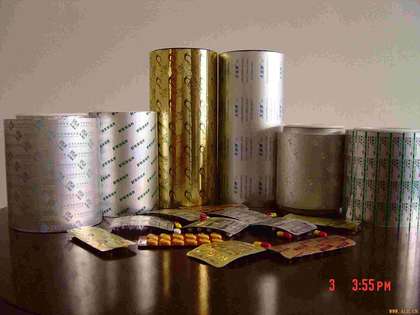

In current pharmaceutical packaging application more composite membrane mainly include the following:

1. The common composite membrane

Typical structure is: the PET/AL/PE, its production process for dry type composite.Product features:

(1) the good printing eligibility, to improve products;

(2) good gas, water vapor barrier property.Widely used in general packaging drugs such as tablets, granules, powder, also can be used as other dosage form drug packaging.

2. Medicinal strip easy tear packaging materials

Typical structure is: the PT/PE/AL/PE excessive packaging, its production process for composite extrusion.Product features:

(1) good easy tear, convenient consumers access to medicines;

(2) good gas, water vapor barrier property, to ensure drug longer shelf life;

(3) good degradability, which is beneficial to environmental protection.Applicable to the effervescent agent, coating agent, capsules, etc. The packing of the drugs.

3. PTP medicinal aluminum foil:

Typical structure as follows:

paper/PE/AL/PE, its production process for composite extrusion.Product features:

(1) the good printing eligibility personalized printing, to improve products;

(2) good stiffness, and ensure the product good formability;

(3) the gas or vapor with good barrier property, can guarantee a long shelf life of pharmaceuticals,

(4) good degradability, which is beneficial to environmental protection.Mainly used in tablet, capsule, powder, granules and other dosage forms the packing of the drugs.

4. High temperature cooking membrane

Typical structure is: the PET/CPP or PET/Al/CPP, its production process for dry type composite.Product features:

(1) basic can kill all the bacteria in the packaging;

(2) can be placed under normal temperature milk packaging without refrigeration.

(3) the water vapor and gas with good barrier property, resistance to high temperature cooking;

(4) can be in printing, good printing eligibility.Mainly used in blood transfusion bag, bag and so on liquid packaging.

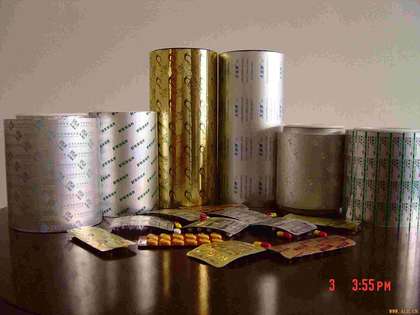

1. The common composite membrane

Typical structure is: the PET/AL/PE, its production process for dry type composite.Product features:

(1) the good printing eligibility, to improve products;

(2) good gas, water vapor barrier property.Widely used in general packaging drugs such as tablets, granules, powder, also can be used as other dosage form drug packaging.

2. Medicinal strip easy tear packaging materials

Typical structure is: the PT/PE/AL/PE excessive packaging, its production process for composite extrusion.Product features:

(1) good easy tear, convenient consumers access to medicines;

(2) good gas, water vapor barrier property, to ensure drug longer shelf life;

(3) good degradability, which is beneficial to environmental protection.Applicable to the effervescent agent, coating agent, capsules, etc. The packing of the drugs.

3. PTP medicinal aluminum foil:

Typical structure as follows:

paper/PE/AL/PE, its production process for composite extrusion.Product features:

(1) the good printing eligibility personalized printing, to improve products;

(2) good stiffness, and ensure the product good formability;

(3) the gas or vapor with good barrier property, can guarantee a long shelf life of pharmaceuticals,

(4) good degradability, which is beneficial to environmental protection.Mainly used in tablet, capsule, powder, granules and other dosage forms the packing of the drugs.

4. High temperature cooking membrane

Typical structure is: the PET/CPP or PET/Al/CPP, its production process for dry type composite.Product features:

(1) basic can kill all the bacteria in the packaging;

(2) can be placed under normal temperature milk packaging without refrigeration.

(3) the water vapor and gas with good barrier property, resistance to high temperature cooking;

(4) can be in printing, good printing eligibility.Mainly used in blood transfusion bag, bag and so on liquid packaging.

※コメント投稿者のブログIDはブログ作成者のみに通知されます