ANY 28mm Cap Mould can often manufacture a plastic bottle cap. This is a good choice for making sports drinks, sodas, and soft drinks. It can as well be used with regard to other bottles, which include milk bottles as well as water bottles. It will come in various sizes, including 30mm, 38mm, and also 48mm. It can also be customized to fit just about any bottle cap. It's got numerous benefits, and can be a great addition for you to any business.

A 28mm neck of the guitar plastic bottle could be made using the Plast Cap Would mould. The 28mm plast cap mould is constructed of new HDPE material allowing it to be custom fashioned. A high-quality Plast Cap mould can be a valuable investment for a business that creates sports drinks. The durability, precision, and affordability ensure it is the ideal option for sports wine beverages. This mould can be highly efficient, cutting down labor and public resource costs.

A 28mm neck of the guitar plast cap mould is done from 100% innovative HDPE material. It can be easily customized as well as used for physical activities drinks, soft food and drink, and other beverages. It is furthermore highly durable, and is very useful both standard along with custom designs. The tailed-made alternative from SINOPK assists you design the great bottle cap mould for the business. You can choose from numerous mould materials in addition to colors.

A 28mm fretboard plast cap mould is made of high-quality HDPE materials. It can be customized for your specific requirements. This can be a great choice for virtually any company that desires to add more features recommended to their products. These features allow it to be a great choice for customizing and producing bottles. Addititionally there is no need to replace the truck tops because this mold is completely custom. It is a smart choice for any packaging company.

A 28mm the neck and throat plast cap mould consists of 100% new HDPE materials. The process of having a 28mm neck plastisol covering mould is fast and simple. A customized product can help you save time and cash. You can tailor-make your bottle hats and create your individual brand identity. There are use your unique design! It is not optional to remember that quality and performance are vital towards your business. The right tool will increase your bottom line and help you meet your pursuits.

A 28mm fretboard plast cap mould can help you save major time and money. A high-quality mould China Preform Mould Factory can grow your production by around 50%. And, it's easy to customize. There are a couple of main advantages to using a custom-designed cap mould. First, it offers you a higher production rate. It is an investment which will pay off eventually. So, if you would like to be more competitive in the market, consider some sort of custom-made mould.

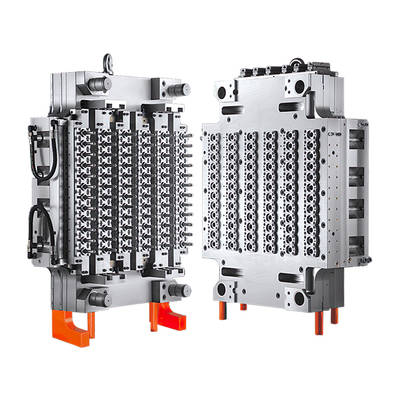

Getting advanced preform moulds could be the core business of Indian PETform. They feature hot-runner systems China Pet Mould Manufacturers with around 144 cavities. On K2019, they introduced a fresh hot-runner development. These molds feature elevated insulation. The advanced materials included in these molds will be titanium and ceramics, which reduce energy ingestion by 15 that will 20%. These materials get lower thermal conductivity in comparison with steel, and can even be biodegradable.

In add-on to multicavity moulds, GDXL Precise Equipment designs and products high-cavity PET moulds for your plastics industry. They have been around in business since 1993, in addition to their products incorporate single and double-cavity FAMILY DOG blow moulds. They may be configured for around 144 cavities and come in many different neck finishes in addition to material technologies. They also offer a selection of neck finishes to check different processes.

Whether your supplement requires a high-cavity mould having a high-volume production rate or a small-scale development process, Rompa will have a multi-cavity mould to chic. The experts at Rompa will work with you to view which type of multicavity mould can best meet your production goals and minimize waste. And so, what are the top features of pet moulds?

The grade of PET Preform Moulds is the same as that of the methods made in Canada. The moulds are manufactured with all the same quality materials as in america. In addition that will high-quality materials, each PET Preform Mould is usually easy to keep. With a wide selection of designs as well as cavity cavities, it can chic, no matter just what your production goals. You can even make your own personal multicavity plastic products easily.

In case you are producing a considerable amount of products, you need a multicavity FAMILY DOG preform mould to generate your production capability. The patented optiRUN technology from MHT Style & Hotrunner Engineering AG greatly minimizes the formation associated with PET dust. This dust is made by gaseous PET fission products for the metallic tool exterior. So, the nozzles might effectively prevent the particular formation of toxic particles through the mould.

A Multicavity Pet Moulds are widely-used to produce huge volumes of goods. It is easy to use and requires tiny maintenance. The molds are constructed with high-quality aluminium, that's suitable for hot-filling creation. It is also best with various PET bottles. The range connected with different cavities allows you to create many size and shapes. These moulds can be found in many sizes, from TEN to 144.

Ideal for mid-size and many package markets, the Husky NexPET mould can be operated on a ton of preform molding stands. It has a lengthier vertical pitch long distance of 60 mm allowing it to accommodate thread diameters approximately 40 mm. The special design provider offers photochemical etching, milling, eroding, along with laser engraving, which can assist you achieve the perfect designs to your pet packaging.