Sliding operation is often used in high-rise buildings where the density of reinforced curtains is high. It reduces the construction time of high-rise buildings. It is also used where continuous pouring of concrete is required. In this way, the arrangement of cold joints and curtains is achieved. For the system to be implemented correctly, the 24-hour program must be properly planned. Although the type of work is continuous in a vertical direction in a circular and prismatic configuration, it can be curved inward or outward if desired. Forms are also used in rectangular, square, hyperbolic and cylindrical shapes. Spectral models are so called because the small but continuous rise makes the model appear to be sliding over a long period of time. A sheet lift system is a system of hydraulic equipment that lifts the material continuously. In this case, depending on the processing time of the material, it can be raised about 150-300 mm per hour. In this process, the concrete will be able to support itself in a short period of time. Based on project specifications and weather conditions, the balance and conditions set in the structure are checked by supervisors using set accelerators or set retarders and objects. The installation is placed on a template (hook) prepared according to the geometric shape of the building to be built. The system consists of herringbone beams (NPU100), steel frames (spur) to be attached to the clamping bolometers, interlocking steel bars (120 cm) manufactured at a certain height to support 10 * struts 20cm. The supports connected to this system form the functional area. The hydraulic spring (about 1.5 meters), which rests on the spur spurs and allows the whole system to move, allows the system to be placed on the climbing rod and the concrete. Installation of fasteners, structural work for doors and windows on the wall, installation of post-tensioning ducts if there are any, installation of additional steel, installation of bolometers and continuing work to develop in general. As the system develops, it is filled with non-stop and controlled time. Casting, support and management are all done in one place. Due to the suspension, added to the structure, the damaged or defective parts are repaired before the material is properly fixed and cured for 24 hours using different chemicals. After these steps, it is ensured that a strong and durable structure is created that is good from start to finish and has the required strength. It arises at a high speed and the input is created and the work is done quickly with significant time savings. It is four to seven times faster than traditional methods.

Since no cold joints are built using the sliding sheet method, it is not allowed to create weak areas in the wall. This makes it clear that the load, accepted in the static assembly, is distributed equally in all directions according to the distribution diagram as expected.

There is no need for other means of transportation such as man lifts, cranes and elevators in the area since access to the formwork on the platform is provided by a vertical tower tower TSN. Since the materials are lifted using hydraulic jacks, the use of cranes in the area is minimal.

Since the slipform system has its own area, the appropriate value of scaffolding is used in the workplace. Since nothing unnecessary is stored, this contributes a lot in bringing cleanliness and order to the construction site.

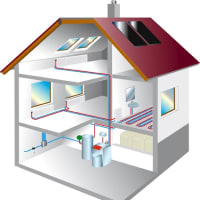

In the picture, one of the parts of the curtain wall is given. A very smooth wall surface is obtained with a sheet that turns on other types.

Website: https://slipform.net/

Since no cold joints are built using the sliding sheet method, it is not allowed to create weak areas in the wall. This makes it clear that the load, accepted in the static assembly, is distributed equally in all directions according to the distribution diagram as expected.

There is no need for other means of transportation such as man lifts, cranes and elevators in the area since access to the formwork on the platform is provided by a vertical tower tower TSN. Since the materials are lifted using hydraulic jacks, the use of cranes in the area is minimal.

Since the slipform system has its own area, the appropriate value of scaffolding is used in the workplace. Since nothing unnecessary is stored, this contributes a lot in bringing cleanliness and order to the construction site.

In the picture, one of the parts of the curtain wall is given. A very smooth wall surface is obtained with a sheet that turns on other types.

Website: https://slipform.net/

※コメント投稿者のブログIDはブログ作成者のみに通知されます