Nanocrystalline magnetic core has high Bs, high effective permeability, high DC bias stability, high temperature stability, wide frequency adaptability, low power consumption, low-cost new soft magnetic material, applied to high power, high frequency, Miniaturized, high conversion rate switching power supply transformers and chokes.

Nowadays, solar energy industry inverters, hydropower, air power, and electric energy conversion and charging for hybrid vehicles have a great market space and future, because the performance of nanocrystalline magnetic cores has extremely high controllability.

The nanocrystalline magnetic core undergoes surface insulation treatment, and is uniformly mixed with the bonding agent, then pressed into shape and annealed. There are basically three ways to obtain nanocrystalline powder: amorphous strips are crushed after annealing and crystallization, mechanical alloying, and molten alloy atomization. At present, mechanical alloying is still in the laboratory research stage, and the amorphous strip crystallization method is produced in small batches by a few companies in China, but the market cannot be expanded due to cost reasons. Compared with other methods, the molten alloy atomization method has high efficiency and low cost. Its disadvantage is that the powder produced has low amorphous content and high loss.

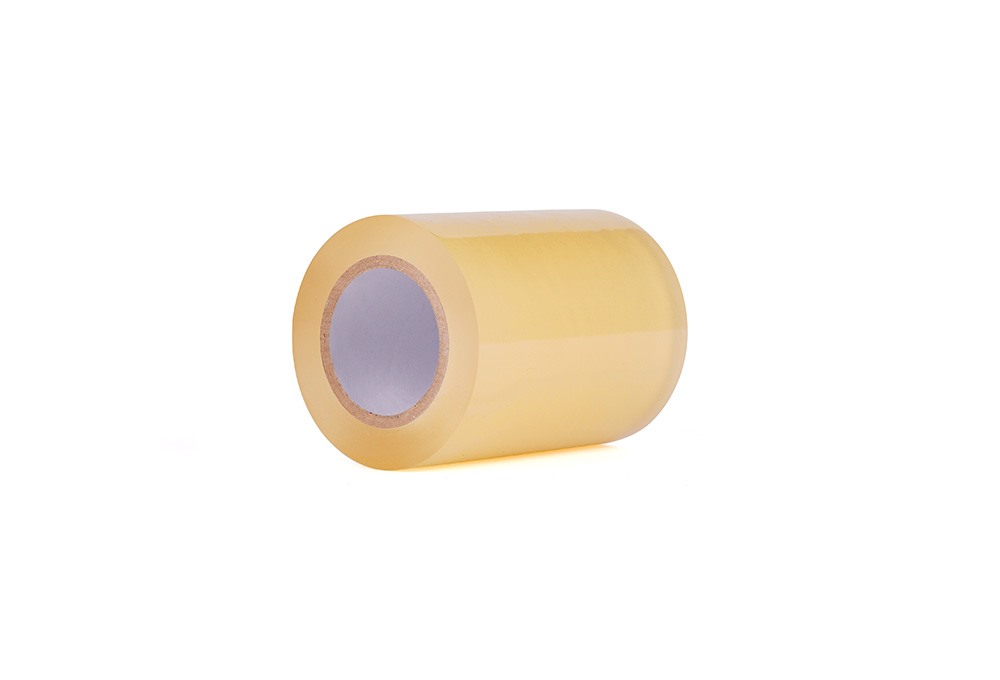

1. High temperature resistant tape is mainly suitable for metal surface treatment of computer cases, cabinets, etc., to protect the high temperature powder from spraying and baking paint.

2. At the same time, high-temperature tape is also suitable for electronic products, automotive industry, coating and other products. When high-temperature spraying, it plays a role of shielding, protection and insulation.

3. High temperature resistant tape will be fixed during the production of printed circuit boards, electronic parts, resistors and capacitors, and during the process of PCB impregnation, it will shield the gold fingers and prevent the plating solution from immersion and pollution. The printed circuit board gold plating has shielding protection. A certain effect.

4. Household appliances, machinery, electronics and other industries also need high-temperature coating and spray paint protection, high-temperature binding and fixing, and high-temperature adhesive tape can solve these problems.

5. High temperature resistant tape is sometimes used as a release paper joint, referred to as connecting tape.

6. It can be used in the drum of sizing machine, thermoplastic demoulding and other industries. The high temperature resistant tape can be used repeatedly and is easy to replace.

7. High temperature resistant tape is widely used in packaging, thermoplastic, compounding, sealing and heat sealing, electronic and electrical industries.

8. Mainly used in the electronics industry. The temperature resistance is usually between 120° and 260°. The high temperature resistant tape is often used for painting, baking varnish leather processing, coating masking and fixing in the manufacturing process of electronic parts, printed circuit boards and high temperature processing masks.