Pyrolytic Boron Nitride is a boron nitride ceramic product that does not react with acids, bases, organic solvents, molten metals or graphite. It can withstand temperatures of 1800 ° C in a vacuum and 2000 ° C in nitrogen, making it ideal for use as a furnace assembly and melting vessel. PBN crucible heated to 1200 ° C can be inserted into liquid nitrogen without causing significant damage. PBN coated graphite heating elements provide an extremely uniform temperature profile for compound and silicon semiconductor fabrication.

By means of the CVD process, it is possible to produce a component of pyrolytic boron nitride or graphite products with numerous properties, which can provide customers with decisive added value:

In ultra-high vacuum applications, the decarburization of pyrolytic boron nitride at the highest temperatures is minimal.

Pyrolytic boron nitride components not affect the chemical reaction or physical properties of the product being tested.

Components made of pyrolytic boron nitride have good toughness and a stable shape.

Pyrolytic boron nitride crucible

CVD is capable of producing tantalum made of pyrolytic boron nitride of different sizes and forms. Such as:

Straight

Conical shape

Special form

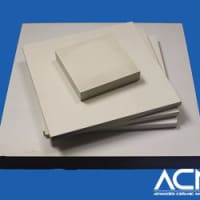

PBN and graphite coating

Using a chemical vapor deposition process, we can coat a suitable graphite material with pyrolytic boron nitride to combine the thermal, chemically stable, and electrically insulating properties of anisotropic PBN with the conductivity of graphite. This means it can make thicker parts such as heaters, furnaces and furnaces.

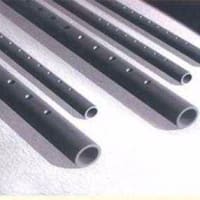

PBN-PG heater

Since pyrolytic boron nitride and pyrolytic graphite can be combined because they have comparable CTE (coefficient of thermal expansion), they can be used to construct a heating element. The light weight and associated good rapid temperature change behavior, as well as the chemical inertness associated with other substances, should be emphasized here. PBN-PG heater can be manufactured in the form of a planar heater or a 3D heater such as a tube.

For more information, please visit https://www.preciseceramic.com/.

By means of the CVD process, it is possible to produce a component of pyrolytic boron nitride or graphite products with numerous properties, which can provide customers with decisive added value:

In ultra-high vacuum applications, the decarburization of pyrolytic boron nitride at the highest temperatures is minimal.

Pyrolytic boron nitride components not affect the chemical reaction or physical properties of the product being tested.

Components made of pyrolytic boron nitride have good toughness and a stable shape.

Pyrolytic boron nitride crucible

CVD is capable of producing tantalum made of pyrolytic boron nitride of different sizes and forms. Such as:

Straight

Conical shape

Special form

PBN and graphite coating

Using a chemical vapor deposition process, we can coat a suitable graphite material with pyrolytic boron nitride to combine the thermal, chemically stable, and electrically insulating properties of anisotropic PBN with the conductivity of graphite. This means it can make thicker parts such as heaters, furnaces and furnaces.

PBN-PG heater

Since pyrolytic boron nitride and pyrolytic graphite can be combined because they have comparable CTE (coefficient of thermal expansion), they can be used to construct a heating element. The light weight and associated good rapid temperature change behavior, as well as the chemical inertness associated with other substances, should be emphasized here. PBN-PG heater can be manufactured in the form of a planar heater or a 3D heater such as a tube.

For more information, please visit https://www.preciseceramic.com/.

※コメント投稿者のブログIDはブログ作成者のみに通知されます