Different industries including, personal care, food & beverages, healthcare, electronics, and consumer goods are witnessing rapid growth in Latin America, Asia-Pacific, and Middle East and Africa, which is majorly due to the strong economic in countries in these regions. For example, as per the International Trade Administration, the healthcare industry in India generated about $110 billion in 2016 and was estimated to attain $280 billion by 2020. The growth of an industry is driven by the increasing demand for its products and services. Because of increasing need for medical devices, electronic devices, and personal care & cosmetic products, the demand for extrusion coating is growing as well.

Extrusion coating can be defined as a process where a coat of thermoplastic material is put on a substrate, such as woven fabric, paperboard, and aluminum foil. The process increases scuff resistance, tear resistance, resistance against chemicals, provides a heat sealable surface, grease resistance, and provides a barrier against different gases and water. Because of these advantages, the global extrusion coating market is predicted to reach a value of over $4,759.3 million by 2023, increasing from $3,703.8 million in 2017, and is expected to register a 4.2% CAGR during the forecast period (2018–2023).

Get a sample copy of this research: https://www.psmarketresearch.com/market-analysis/extrusion-coating-market/report-sample

The material types that are utilized for extrusion coating are polypropylene (PP), low-density polyethylene (LDPE), and ethylene-vinyl acetate (EVA). Among all these, the demand for LDPE was the highest in the past, which is ascribed to the fact that LDPE is utilized extensively in the production process of films that are used as bags, packaging materials, and sacks. Other than this, the demand for PP is also predicted to grow considerably in the near future, on account of the increasing utilization of this material in food & beverage packaging as it is flexible and tough.

Aluminum foil, paper and paperboard, and polymer film are the different kinds of substrates on extrusion coating is done. Among all these, a significant demand for extrusion coating materials is expected to be created for polymer film in the near future. This can be due to the rising requirement for flexible packaging solutions in several industries, such as healthcare, food & beverages, and personal care. Polymer film is utilized in these industries for protecting products from vibration, shock, and surface tension. The major applications of extrusion coating are photographic, liquid packaging, commercial, and flexible packaging, among which, the demand for liquid packaging has been the highest.

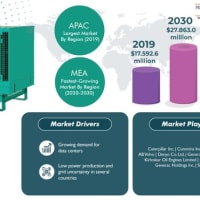

Extrusion coating is widely utilized in liquid packaging applications for increasing the salability of various types of semi-solid and liquid food items, including sauce, milk, and juice. When geography is taken into consideration, the Asia-Pacific (APAC) region has been the largest extrusion coating market up till now, which is particularly because of the rising disposable income of people, and rapid industrialization in the region that is boosting the need for extrusion coating materials for packaging purposes. Within the region, China is the major consumer of extrusion coating materials.

Hence, the demand for extrusion coating is growing due to the rapid economic growth in developing countries.

※コメント投稿者のブログIDはブログ作成者のみに通知されます