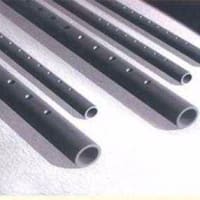

Ceramic rods are mainly formed by zirconia ceramics or alumina ceramic materials through molding, sintering and processing. Ceramic rods have been widely used in military, aerospace, industrial and other fields and those markets have a large demand for ceramic rods. The demand for ceramic rods varies from industry to industry, and their requirements are different. But the main considerations are the same: wear resistance, thermal insulation and high temperature resistance, corrosion resistance, lubrication.

The main materials of ceramic rods are mainly zirconia ceramics and alumina ceramics. What is the difference between these two types of ceramic rods?

Zirconia ceramic rods:

Zirconia, or Zirconium dioxide (ZrO2), is a white crystalline oxide of zirconium. Its most naturally occurring form is the mineral baddeleyite with a monoclinic crystalline structure. Cubic zirconia is adopant stabilized cubic structured zirconia, and it can be synthesized in various colors for use as a gemstone and a diamond simulant.

The biggest advantage of zirconia ceramic rods is their very good toughness. Zirconium oxide ceramic rods are widely used in the fields of motor shafts, motor shafts, grinding, needle gauges, etc. In particular, ceramic center rods are used in the field of heat dissipation products to replace traditional stainless steel center rods.

Alumina ceramic rods:

Alumina, orAluminium oxide, is a chemical compound of aluminium and oxygen with the chemical formula Al2O3. It is the most commonly occurring of several aluminium oxides, and specifically identified as aluminium(III) oxide. It is commonly called alumina and may also be called aloxide, aloxite, or alundum depending on particular forms or applications.

Alumina ceramic rods can withstand high temperatures up to 1700 degrees, have good conductivity, mechanical strength and high temperature resistance. The density of alumina ceramic rods is relatively low and convenient for transportation. However, alumina ceramic rods have poor toughness and are easy to break and break. Alumina ceramic rods are widely used, and have been soaked in various fields such as electronic appliances and mechanical parts.

For more information, please visit https://www.preciseceramic.com/.

The main materials of ceramic rods are mainly zirconia ceramics and alumina ceramics. What is the difference between these two types of ceramic rods?

Zirconia ceramic rods:

Zirconia, or Zirconium dioxide (ZrO2), is a white crystalline oxide of zirconium. Its most naturally occurring form is the mineral baddeleyite with a monoclinic crystalline structure. Cubic zirconia is adopant stabilized cubic structured zirconia, and it can be synthesized in various colors for use as a gemstone and a diamond simulant.

The biggest advantage of zirconia ceramic rods is their very good toughness. Zirconium oxide ceramic rods are widely used in the fields of motor shafts, motor shafts, grinding, needle gauges, etc. In particular, ceramic center rods are used in the field of heat dissipation products to replace traditional stainless steel center rods.

Alumina ceramic rods:

Alumina, orAluminium oxide, is a chemical compound of aluminium and oxygen with the chemical formula Al2O3. It is the most commonly occurring of several aluminium oxides, and specifically identified as aluminium(III) oxide. It is commonly called alumina and may also be called aloxide, aloxite, or alundum depending on particular forms or applications.

Alumina ceramic rods can withstand high temperatures up to 1700 degrees, have good conductivity, mechanical strength and high temperature resistance. The density of alumina ceramic rods is relatively low and convenient for transportation. However, alumina ceramic rods have poor toughness and are easy to break and break. Alumina ceramic rods are widely used, and have been soaked in various fields such as electronic appliances and mechanical parts.

For more information, please visit https://www.preciseceramic.com/.

※コメント投稿者のブログIDはブログ作成者のみに通知されます