CPVC pipe is produced from a specialty blend of chlorinated polyvinyl chloride material with unique physical properties desirable for piping applications (i.e., improved impact resistance and good fire resistance capabilities). Pipe grade CPVC product line includes schedules 40 and 80 piping from 1/4″ through 24″ diameters. CPVC piping systems can handle more than three-fourths of the temperature/pressure requirements of today’s typical process plants. CPVC pressure pipe has an upper working temperature limit of 200° F (93° C), or approximately 60° F (15° C) above that of Type I Grade I PVC. As with all thermoplastic piping systems, CPVC’s ability to withstand pressure varies with pipe diameter, wall thickness, and temperature. As the pipe diameter and temperature increases, the pressure rating of the product decreases. For example, 1/2″ Schedule 80 CPVC pipe is engineered for continuous service of 850 psi @ 73°F (23°C). The same pipe in service @ 180°F (82°C) carries a maximum working pressure rating of 210 psi at this temperature. 6″ Schedule 80 CPVC pipe is designed for 270 psi @ 73°F, and 54 psi @ 200°F.

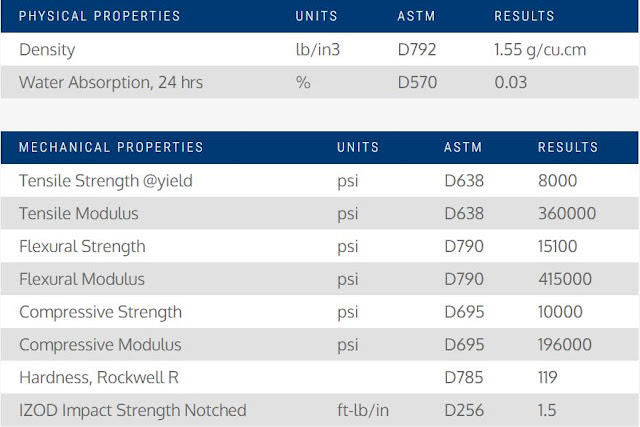

PROPERTIES

NOTE: The property values presented above are typical values intended for reference and comparison purposes only. They should NOT be used as a basis for design specifications or quality control.

APPLICATIONS:Welded Tanks, liners;Valves, fittings, and piping systems;Ducts;Pumps.

ADVANTAGES:High impact strength;Dimensionally stabile;Easily machined using standard metal working tools;Corrosion resistant;Easily cemented and welded;Lightweight;Excellent electrical properties;Excellent fire rating;Good chemical resistance.