♣ When wastewater treatment is performed by the conventional aeration method, it is always supersaturated with nitrogen gas and carbon dioxide components. (Measurement example using Gas Chromatograph:O2 0.5mg/L, N2 19.0mg/L, CO2 40.0mg/L)

Click! ➽ https://www.youtube.com/watch?v=KXTroWf0w40

This device increases the amount of dissolved oxygen in the sewage without the need for additional energy sources.

It is therefore quite different from the aeration principle using diffusers.

The best sewage conditions are the same, both in terms of the rate of gas absorption, which dissolves the necessary gaseous components in the air into the sewage, and the rate of gas release, which releases unnecessary air components from the sewage.

The best sewage condition is the thin liquid film of sewage produced in the air reservoir in the AWA device or in the air reservoir in the aeration booster, which is placed in the sewage.

The current aeration systems used in wastewater treatment plants and the bubble towers used in the chemical industry only bubble the desired gaseous components in the liquid.

They are therefore less efficient in replacing unwanted gaseous components already dissolved in the liquid, and naturally less efficient in dissolving the desired gaseous components.

Aeration booster

Click ➽ https://www.youtube.com/watch?v=M9eGhaJIR78

Actively generete bubbles Click! ➽ https://www.youtube.com/watch?v=7Ps6jkJH47Y

United States Patent

Click ➽ https://patents.google.com/patent/US10857506B2/en?oq=US10857506

AWA Aeration System

Behavior video Click ➽ https://www.youtube.com/watch?v=4ByXpZEuYz0

The video at the URL above shows that the dissolved oxygen in the treatment tank can be increased to values close to 3mg/L by using the AWA Aeration System without increasing the air supply.

In this experiment, the dissolved oxygen increased from 1mg/L to 3mg/L.

Even if the dissolved oxygen in the treatment tank is less than 0.3 mg/L, it can be increased to more than 3 mg/L by replacing the AWA aeration system.

By simply catching the air bubbles that rise to the surface in the sewage, the system can increase the amount of dissolved oxygen in the sewage treatment tank.

Rather than thinking of this phenomenon as the dissolution of oxygen gas components, please think of it as the "dissolution of oxygen gas components in the air" as a result of the release of unnecessary dissolved gas components. (The same phenomenon occurs with the aeration booster.)

▶▶The air component cannot be dissolved from the air bubbles floating in the water.

Internal behavior slow video Click ➽ https://www.youtube.com/watch?v=R0R50mFIhpM

Click ➽ https://www.env.go.jp/water/asia_business/pdf/R1_earth-creative_en.pdf

★No matter how small the air component is made into fine bubbles, it cannot be dissolved in saturated water (e.g. tap water) or oversaturated water (e.g. sewage from a sewage treatment plant).

Particularly in oversaturated water, the extra dissolved gaseous components are released into the space inside the microbubbles, causing the microbubbles to expand rapidly and most of them to float due to increased buoyancy.

Click! ➽ https://www.youtube.com/watch?v=KXTroWf0w40

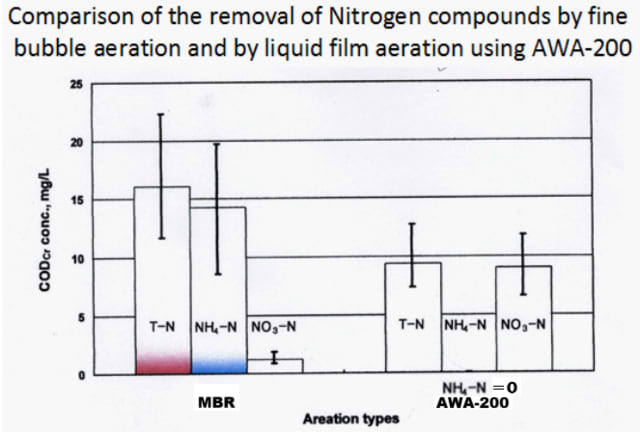

★None of the sewage in the sewage treatment plant is in a state of degassing.

It is almost always supersaturated with gaseous components other than oxygen.

Bubbletank

http://ww52.tiki.ne.jp/~bubbletank/

E-mail bubbletank@mx52.tiki.ne.jp