Above is showing the one coated with polyurethane on the left and the other simply oiled to the right of it. I very much like the oiled bed. The darker middle has a deeper shade to it. However, I have made a final decision.

I will go for polyurethane coating. Simplest reason is the smell from the coating agent. With polyurethane there is no odor, to speak of, anyway, but the oiled bed smells, not pungent, of course, and it is rather aromatic. However, some people are sensitive enough.

These are also polyurethane coated and expect 8 more coating sessions.

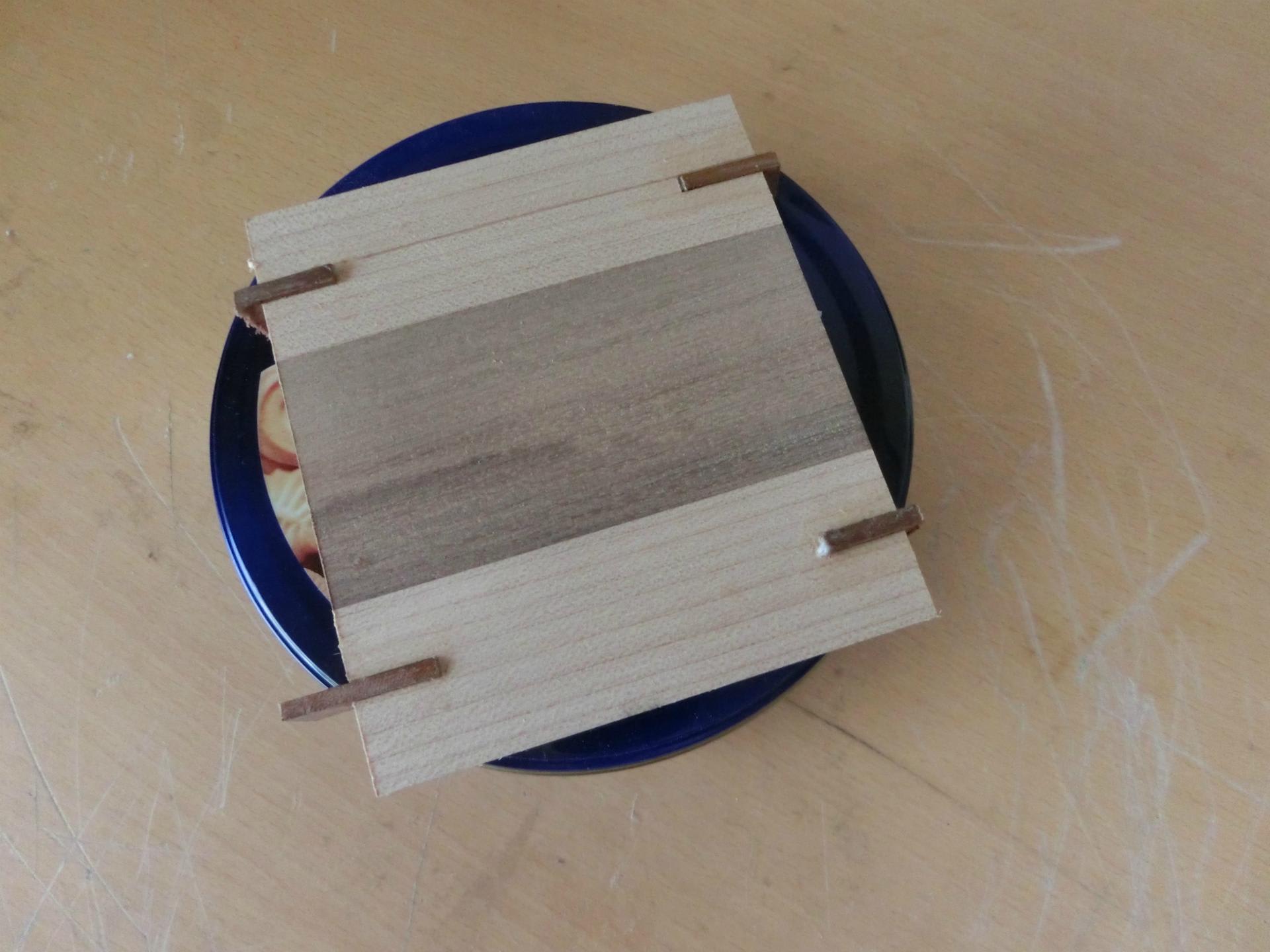

Below is the photo of a very simple square bed, no legs.

In addition, I am now forming another idea. That is, even thinner beds (or plates, rather),with or without supporting legs. They will be looking more or less like this one, except that they will be longer.

Yesterday and today, I encountered two more significant issues. The easiest to explain is the holding jig for incision making. I talked about this earlier. However, it was all bullshit. Suffice to show two photos in succession.

As you see here above it is a much simpler system, because same aluminum piece is rotated to cater for different incision heights. This is a delicate issue and I will not go into its details. Case closed, for ever...

Now, turning to hashi holding jig, see below.

This jig is at an angle (copying the hashi slope underneath) with respect to the horizon, with a cutout at the end where one end of the hashi-to-be plank is going to rest.

The idea was that when this jig is placed horizontally the cutout angle will inherit the original hashi tapering angle. The whole idea is murky and I want to forget about this idea.

My newer idea was as follows.

1. If I am to use metals they should nor come into contact with the plane blade.

2. Material loss should be kept to a minimal.

3. Planing need not be done down the whole length of the hashi pieces.

4. Jig configuration should be easily modifiable to cater for different lengths of the hashi.

If I am to take all these into consideration my holding jig setup will be something like:

1. A piece of wood fixed at the forward end of the plane bed, with a J clump (or G clump).

2. A thin aluminum plate underneath thicker end of the plank.

3. Mid thickness line drawn at the forward end of the plank.

Yes, with the stopper at the forward end I may not require this metal plate at the thicker end. On the other hand , if the tapering continues equally and evenly down the whole length of the hashi I will be needing to plane the thicker end infinitesimally close to its final dimension.

That will be awfully tricky. However, knowing that forward motion will be stopped automatically I need not to worry about metal contact. So, in place of an infinitesimally small gap I should be able to get away with a 1 mm thick metal plate.

All I actually need is to fix an L shaped metal at the forward end of the (hashi) pusher. I will have a go at it tomorrow...