Conchita, as I said in the Spanish como se dice I went along

to a new shop with whom I can deal with my products.

I left some of my sample products there.

I will be helping her with the interior design for

free of charge. She is muy simpatica!

Anyway, most, or almost all of this afternoon was spent on

turning two saucers from domestic walnut. I was anxious that

I complete this work soonest. Other things are in the pipeline

and I cannot afford to waste my time, before setting out

for my house building work.

Today's first photo here is the starter. It is domestic.

Thickness is at 37mm, an industry standard, but I could do with

somewhat thicker materials, but they are hard to come by...

Now, above, the thing is set on the the lathe before turning.

See that it is far from a true circular? I used to use

my bandsaw to make these as circular as possible.

However, these days, I no longer bother. I just make these

true circular starting from this stage.

After a few minutes, I have a true circular, as you see above.

After how long? 10 minutes? I have above.

Now, this is the back of the piece, having been secured to the

lathe with a simple metal piece called "face plate". It is

screwed to the work. The side of the work is already done.

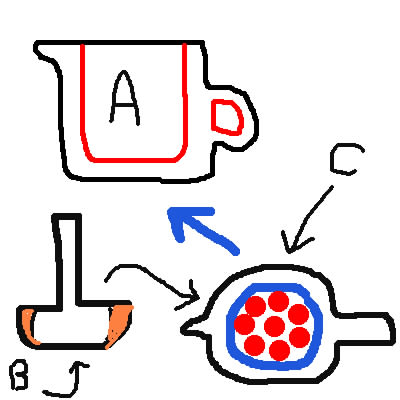

Above is showing you a typical grabber. This one, I mail-

ordered from US, and in fact it alone is more expensive than my

Taiwan made lathe system itself!

Now, having done the concave surface you need to work on the bottom side

of the saucer. This is another grabber I mail-ordered from US.

The earlier grabber is called Talon, and is mighty powerful

in gabbing things. However, this one is only for light work.

Because, grabbing is by these 8 dark plastic discs.

One slight problem with this grabber is that its mas is

large, and once rotating it acquires a staggering amount

of angular momentum. That is to say it does not want to

come to a halt in a short period of time.

This is a pain in the neck, but something I have to live with...

These are the final products. Each selling for something like

JPY 2500, or 3000. Mind you, these will also be coated

10 times!

Coating continued, but there are no photos. Tommorrow will

be spent on a one piece milk pitcher. I am actually

excited about it. I have never done it before, excpet

a larger mug which I presented to somebody I know.

I know that I will have to use all of my skills

and instruments and machines, and tools and bits!

to a new shop with whom I can deal with my products.

I left some of my sample products there.

I will be helping her with the interior design for

free of charge. She is muy simpatica!

Anyway, most, or almost all of this afternoon was spent on

turning two saucers from domestic walnut. I was anxious that

I complete this work soonest. Other things are in the pipeline

and I cannot afford to waste my time, before setting out

for my house building work.

Today's first photo here is the starter. It is domestic.

Thickness is at 37mm, an industry standard, but I could do with

somewhat thicker materials, but they are hard to come by...

Now, above, the thing is set on the the lathe before turning.

See that it is far from a true circular? I used to use

my bandsaw to make these as circular as possible.

However, these days, I no longer bother. I just make these

true circular starting from this stage.

After a few minutes, I have a true circular, as you see above.

After how long? 10 minutes? I have above.

Now, this is the back of the piece, having been secured to the

lathe with a simple metal piece called "face plate". It is

screwed to the work. The side of the work is already done.

Above is showing you a typical grabber. This one, I mail-

ordered from US, and in fact it alone is more expensive than my

Taiwan made lathe system itself!

Now, having done the concave surface you need to work on the bottom side

of the saucer. This is another grabber I mail-ordered from US.

The earlier grabber is called Talon, and is mighty powerful

in gabbing things. However, this one is only for light work.

Because, grabbing is by these 8 dark plastic discs.

One slight problem with this grabber is that its mas is

large, and once rotating it acquires a staggering amount

of angular momentum. That is to say it does not want to

come to a halt in a short period of time.

This is a pain in the neck, but something I have to live with...

These are the final products. Each selling for something like

JPY 2500, or 3000. Mind you, these will also be coated

10 times!

Coating continued, but there are no photos. Tommorrow will

be spent on a one piece milk pitcher. I am actually

excited about it. I have never done it before, excpet

a larger mug which I presented to somebody I know.

I know that I will have to use all of my skills

and instruments and machines, and tools and bits!