Not cutting out the lateral silhouette of a spoon, using a band saw, has advantages. First and foremost is that there is no need to keep the block of wood upright in a stable manner.

True, the band saw itself is always running vertically and anything that it is cutting is kept automatically vertical. That is the theory. At the end of the day, though, you need to use your fingers to make sure the block does not migrate or jump about, and fingers are always so close to the blade, with all the possible consequences one can think of...

In addition, the blade would have to be cutting very close to the block surfaces. Take a look at the lateral profile in the following picture.

Halfway down the bottom length and towards the front end of the spoon the blade would have to be cutting at a glancing angle. On top of that tiny pieces of wood from the blade will be obscuring the pencil lines.

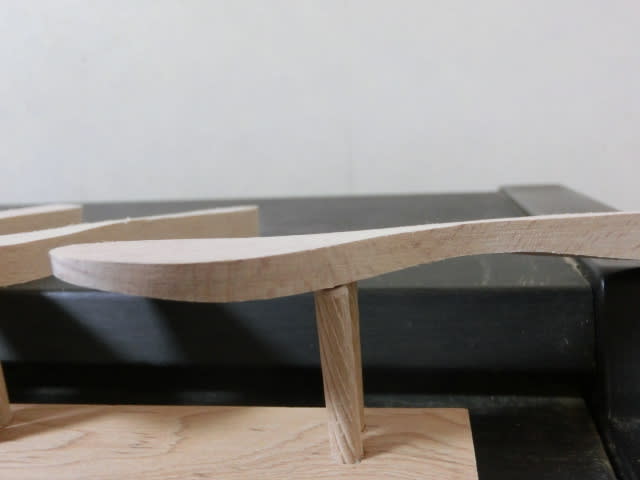

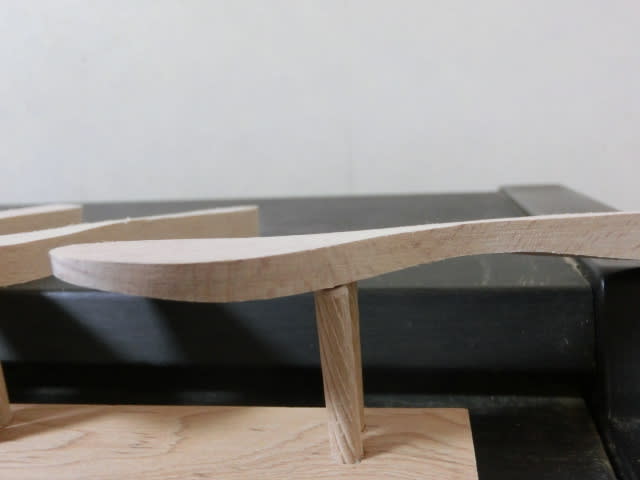

All in all, it is now my firm policy that all future lateral profiles will be sanded out, after cutting the top profiles. Case closed, forever. Now, let us take a look at the front end of a spoon. You can see them here.

Front end thickness of these spoons is almost always 3 mm. I do not make measurements to arrive at this particular thickness. I certainly look at the tips, from time to time, but never measure them. It is sheer dexterity.

Anyway, the mass must be evenly distributed, right and left, as seen front end on, and you can see that with this picture. At this stage, they can be made into spoons, or alternatively they can be made into forks, as you can see in the following picture.

Forks are made using a milling machine to produce grooves, and it is not that complicated, with the knowledge that spoons and forks share the same curvatures. It is interesting, and it was interesting enough when I first discovered this fact. I would have thought they were totally different animals.

Going back to the second picture for today, the edges are simply sanded down to 2 mm, then further sanded down to 1 mm before finger held sanding papers are used. The inner mass is roughed out, very strongly abrasively first, then cleaned softly abrasively.

Yes, I am trying to be sufficiently vague about the inner surface...