It is still too warm these days!

And, the games are there to watch, eating into

half of my normal working hours!

Take a look at the following photo.

Here, you find two chopstics containers, just

recently completed, along with some chopstics.

The issue here is this. What will happen if these containers are

properly coated? I do not have the answer...

Will they open up easily? You can only try...

I cannot coat them all, and these are therefore for

experimental purposes, really. I will see what it will be

like.

See next.

And, see yet next.

All of these were subjected to coating today, the very

first of penetration coatings. You see some photos of those

bellow.

In above, the containers are there to be seen.

Here are the shortest ones...

Apart from the coating, here on follow some on

today's output.

, meaning that I only completed only a single pair of chopstics!

all in addition to some butter knives!

What is above all about? It is a simple piece of thin

and redundant wood. I have problems, these days, trying

to pick up "somen" noodles from the plate.

They are too slippery, for ordinary chopstics and what I have in

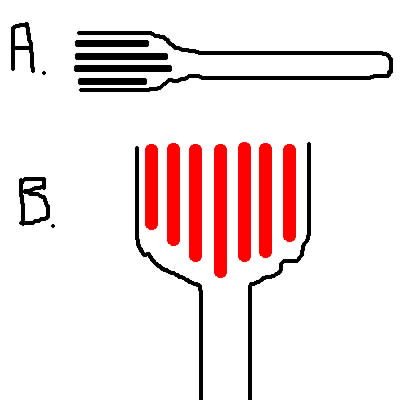

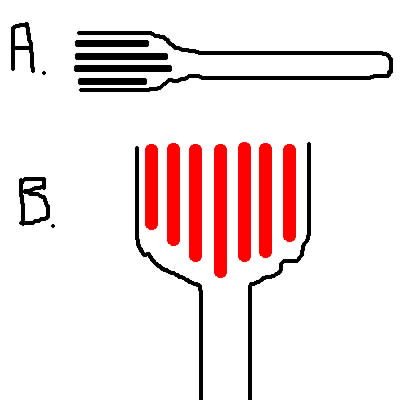

mind is something like as depicted in the next illustration.

Yes, I have something like a comb in mind, with a lot of

pointing members...

Anyway, I have not quite yet finished with the chopstics

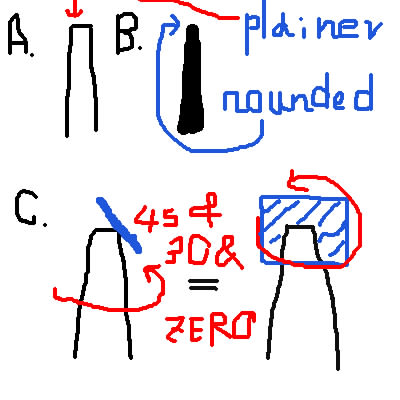

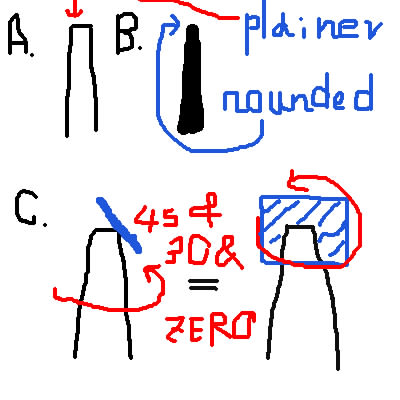

fabrication. Take a look at the next image. This is in relation

to the tip formation.

You narrow down on the picking ends, but the very ends

are flat at the top, as you see with A. You must ronud them.

The rounded tip is shown as B. How you actually round the

tips is depicted with C. Basically, you rotate your stick,

and while doing that, you apply your sanding paper, typically

at the grain level of 240, or 320, applied at the tip,

initially at 45 degrees, gradually, to 30 degrees, and then,

zero degree.

The blue line on the left is the paper and that on the right

is a piece of the paper, seen dead on. The strategy here is

that you also rotate the piece of the sanding paper as shown.

That is, the chopstic axis rotates, and the sanding paper

also does the winding motion at angles to the sharp and

circular edges, all trying to get the best rounded tip head!

You may say it is only about simple chopstics, but I can

and must say that there are issues to be looked at with care!

Am I making myself clear at all? I am no longer sure...

All that there is to it is tricky, and is that

what I mean?

And, the games are there to watch, eating into

half of my normal working hours!

Take a look at the following photo.

Here, you find two chopstics containers, just

recently completed, along with some chopstics.

The issue here is this. What will happen if these containers are

properly coated? I do not have the answer...

Will they open up easily? You can only try...

I cannot coat them all, and these are therefore for

experimental purposes, really. I will see what it will be

like.

See next.

And, see yet next.

All of these were subjected to coating today, the very

first of penetration coatings. You see some photos of those

bellow.

In above, the containers are there to be seen.

Here are the shortest ones...

Apart from the coating, here on follow some on

today's output.

, meaning that I only completed only a single pair of chopstics!

all in addition to some butter knives!

What is above all about? It is a simple piece of thin

and redundant wood. I have problems, these days, trying

to pick up "somen" noodles from the plate.

They are too slippery, for ordinary chopstics and what I have in

mind is something like as depicted in the next illustration.

Yes, I have something like a comb in mind, with a lot of

pointing members...

Anyway, I have not quite yet finished with the chopstics

fabrication. Take a look at the next image. This is in relation

to the tip formation.

You narrow down on the picking ends, but the very ends

are flat at the top, as you see with A. You must ronud them.

The rounded tip is shown as B. How you actually round the

tips is depicted with C. Basically, you rotate your stick,

and while doing that, you apply your sanding paper, typically

at the grain level of 240, or 320, applied at the tip,

initially at 45 degrees, gradually, to 30 degrees, and then,

zero degree.

The blue line on the left is the paper and that on the right

is a piece of the paper, seen dead on. The strategy here is

that you also rotate the piece of the sanding paper as shown.

That is, the chopstic axis rotates, and the sanding paper

also does the winding motion at angles to the sharp and

circular edges, all trying to get the best rounded tip head!

You may say it is only about simple chopstics, but I can

and must say that there are issues to be looked at with care!

Am I making myself clear at all? I am no longer sure...

All that there is to it is tricky, and is that

what I mean?

※コメント投稿者のブログIDはブログ作成者のみに通知されます