I wanted to do something different today, which started with me

taking my wife to Kamakura in the morning.

What I had in mind is shown in the following image.

They are my habanero scoopers, short at 97 mm, and they have

small bores. I made, perhaps, a dozen of them before. Today's

problem was, "How the hell did I make them!", really.

The short and thin item at the bottom is a picker, and

you can see one fork done, and I have got another

20 or so, to be sanded.

Well, that is an aside, and today's issues were manyfold!

Having made them before does not mean much, unless,

you remember how. So, in a way today, I had to start

from scratch!

Now, take a look at the following image. Bores have been

created in the work pieces of six.

Yo must do this, before anything else you do! Because,

you have to align the bore centre to the centre line

of the work pieces. If you have formed the stems before

this operation, you will regret it very much!

In all this, I think I was driven by my instinct

to the final stage, which you have seen as IMAGE 1.

What follows is showing you stem formation.

It is not realistic at all to transcribe their top

profiles, using a template. This is because templates are

not perfect, not even symmetrical, if best made.

Of course, true to say that human eyes cannot easily

recognise the lack of synmmetry. Nonetheless, they are there!

By far the easiest way to form the stems, to match the

bores, is to use those alminium pieces shown here in the photo.

They are, cross-sectionwise, shaped in the form of L.

They can be placed on the workpieces and used to draw

equi-distant lines from the edges.

That, of course, assumes, that those bores have been

allinged to the centre line of the work pieces.

However, that is where my dexterity comes in.

If you cannot put the bores in the centre, then why

bother to continue with these tricky operations?

You are not going to belive this, but, I can easily

recognise true vertical and true horizontal lines,

of course, with reference to properly established

reference lines. And, that ability helps, in centreing the bores.

What is shown below is an interim picture.

You can see that there are new redundancies, as well as

the target work pieces, on their way to becoming

my habanero scoopers!

They will remain redundant, unless you can think of something

useful with them. One of these short pieces was made

into a picker, as shown in the first image.

That is about the only way I can think of...

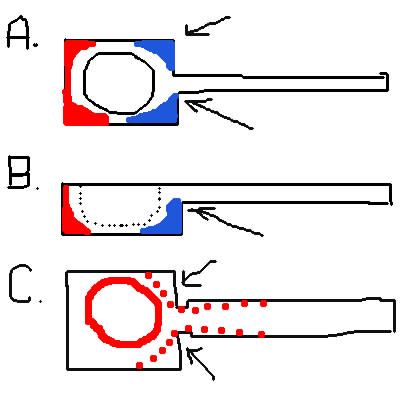

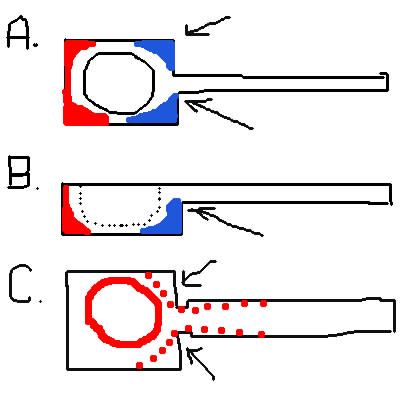

Now, take a look at the following illustration. This is

really showing you the difficulties that follow, from

the image above.

You want them to be nice and shapely, in the end...

However, it is simply difficult. For a start, they are

small, difficult for hold onto during sanding.

To reach your goals, you need to loose mass, and

in A, the red area is OK. With the stem pointing

upward, you can loose the red area, fairly easily.

That is the same with the ide profile, shown in B.

Difficulties come in in the blue areas. Throughout,

the machine used is my belt sander.

Loosing the blue areas is the most challenging part

of this operation, because, not shown in A nor B,

there are discontinuities, as shown by the arrows in C.

Negotiating these discontinuities is the paramount

problem, and I do not want to go into the details, but,

they can be removed, eventually.

I think I have had enough for now.

taking my wife to Kamakura in the morning.

What I had in mind is shown in the following image.

They are my habanero scoopers, short at 97 mm, and they have

small bores. I made, perhaps, a dozen of them before. Today's

problem was, "How the hell did I make them!", really.

The short and thin item at the bottom is a picker, and

you can see one fork done, and I have got another

20 or so, to be sanded.

Well, that is an aside, and today's issues were manyfold!

Having made them before does not mean much, unless,

you remember how. So, in a way today, I had to start

from scratch!

Now, take a look at the following image. Bores have been

created in the work pieces of six.

Yo must do this, before anything else you do! Because,

you have to align the bore centre to the centre line

of the work pieces. If you have formed the stems before

this operation, you will regret it very much!

In all this, I think I was driven by my instinct

to the final stage, which you have seen as IMAGE 1.

What follows is showing you stem formation.

It is not realistic at all to transcribe their top

profiles, using a template. This is because templates are

not perfect, not even symmetrical, if best made.

Of course, true to say that human eyes cannot easily

recognise the lack of synmmetry. Nonetheless, they are there!

By far the easiest way to form the stems, to match the

bores, is to use those alminium pieces shown here in the photo.

They are, cross-sectionwise, shaped in the form of L.

They can be placed on the workpieces and used to draw

equi-distant lines from the edges.

That, of course, assumes, that those bores have been

allinged to the centre line of the work pieces.

However, that is where my dexterity comes in.

If you cannot put the bores in the centre, then why

bother to continue with these tricky operations?

You are not going to belive this, but, I can easily

recognise true vertical and true horizontal lines,

of course, with reference to properly established

reference lines. And, that ability helps, in centreing the bores.

What is shown below is an interim picture.

You can see that there are new redundancies, as well as

the target work pieces, on their way to becoming

my habanero scoopers!

They will remain redundant, unless you can think of something

useful with them. One of these short pieces was made

into a picker, as shown in the first image.

That is about the only way I can think of...

Now, take a look at the following illustration. This is

really showing you the difficulties that follow, from

the image above.

You want them to be nice and shapely, in the end...

However, it is simply difficult. For a start, they are

small, difficult for hold onto during sanding.

To reach your goals, you need to loose mass, and

in A, the red area is OK. With the stem pointing

upward, you can loose the red area, fairly easily.

That is the same with the ide profile, shown in B.

Difficulties come in in the blue areas. Throughout,

the machine used is my belt sander.

Loosing the blue areas is the most challenging part

of this operation, because, not shown in A nor B,

there are discontinuities, as shown by the arrows in C.

Negotiating these discontinuities is the paramount

problem, and I do not want to go into the details, but,

they can be removed, eventually.

I think I have had enough for now.