Conchita, one of the things I tried today was to make holes

in a shpere. Next few photos are showing you jig making and

how my small spheres are fitting into the sphere holding space.

These fabricated shperes will be used, how? A's wants these and I made them, anyway.

These below are my rice spatulas going mat. Surprisingly,

at A's a couple of these were sold. I understand the

reason, I think. Not much more different from plastic

spatulas, but the quality is there and that is too obvious

if you care to look at my spatulas. Anyway, these are meant for

the department sales.

Above here just showing you the chopstics cases undergoing

coating by A polyurethane for the second time. Magnets and

soft iron pegs have been inserted into the holes and fixed.

However, another idea came about. With these cases shown

above you must pull them apart to take out your chopstics.

Why can we not have cases as shown above in the schematic

where lids just swing open? That would be far better than

pulling the lids apart.

In order to achieve that you need a fulcrum and B

in the same schematic is looking at the possibility

of having a wooden bolt like peg.

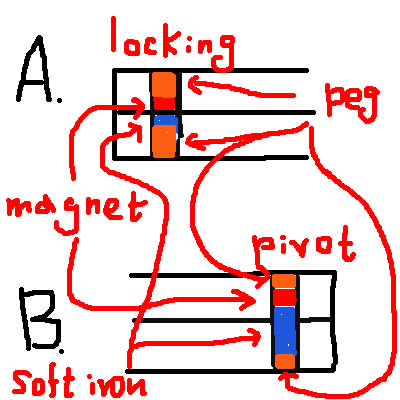

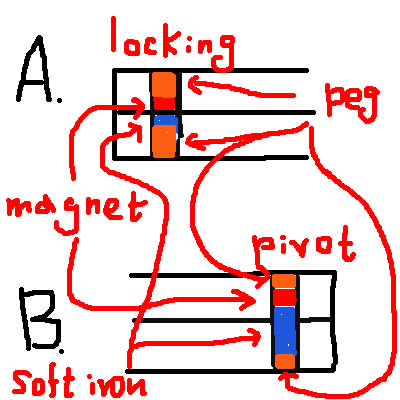

Schematic above is looking at how we might achieve this

kind of pivotal arrangement. This is actually far

cumbersome, and is almost imppossible to achieve.

This schematic above is pointing towards the way forward.

In place of having a complicated wooden pivotal peg my idea

now is to use the existing know-how of dealing with magnets and

soft iron pieces. A is one end with the locking (very nearlly)

mechanism, and B is the falcrum end. At the falcrum end

the soft iron piece goes much deeper than is suggested by B.

At the A end, no protrusion either by the magnet or

by the soft iron. Therefore, you would expect

a little bit of shear at this end because the lids

at this end could slide over each other, unless there is

a proper locking mechanism. I have given some thought

to this issue (such as shallow cuts). My conclusion is

that it is not worth any further efforts. This end is

self-correcting, anyway.

And the other end (B) is also attractively fixed as a pivot.

The whole mechanism looks a little tricky, but right in

front of me I have an experimental piece.

My gut feeling is that you need something like 100g or

more of pulling weight at the end A to cause a significant

amount of shear and on top of that it is ever so easy to

get them back into the right position due to the presence

of magnetic attraction.

Conchita, so, we have been looking at how an idea follows from

another. In any event, have you seen chopstics cases

opening like a pair of scissors?

in a shpere. Next few photos are showing you jig making and

how my small spheres are fitting into the sphere holding space.

These fabricated shperes will be used, how? A's wants these and I made them, anyway.

These below are my rice spatulas going mat. Surprisingly,

at A's a couple of these were sold. I understand the

reason, I think. Not much more different from plastic

spatulas, but the quality is there and that is too obvious

if you care to look at my spatulas. Anyway, these are meant for

the department sales.

Above here just showing you the chopstics cases undergoing

coating by A polyurethane for the second time. Magnets and

soft iron pegs have been inserted into the holes and fixed.

However, another idea came about. With these cases shown

above you must pull them apart to take out your chopstics.

Why can we not have cases as shown above in the schematic

where lids just swing open? That would be far better than

pulling the lids apart.

In order to achieve that you need a fulcrum and B

in the same schematic is looking at the possibility

of having a wooden bolt like peg.

Schematic above is looking at how we might achieve this

kind of pivotal arrangement. This is actually far

cumbersome, and is almost imppossible to achieve.

This schematic above is pointing towards the way forward.

In place of having a complicated wooden pivotal peg my idea

now is to use the existing know-how of dealing with magnets and

soft iron pieces. A is one end with the locking (very nearlly)

mechanism, and B is the falcrum end. At the falcrum end

the soft iron piece goes much deeper than is suggested by B.

At the A end, no protrusion either by the magnet or

by the soft iron. Therefore, you would expect

a little bit of shear at this end because the lids

at this end could slide over each other, unless there is

a proper locking mechanism. I have given some thought

to this issue (such as shallow cuts). My conclusion is

that it is not worth any further efforts. This end is

self-correcting, anyway.

And the other end (B) is also attractively fixed as a pivot.

The whole mechanism looks a little tricky, but right in

front of me I have an experimental piece.

My gut feeling is that you need something like 100g or

more of pulling weight at the end A to cause a significant

amount of shear and on top of that it is ever so easy to

get them back into the right position due to the presence

of magnetic attraction.

Conchita, so, we have been looking at how an idea follows from

another. In any event, have you seen chopstics cases

opening like a pair of scissors?