Conchita, the first one here is showing you how to determine

the thickness of the material you want for this kind of side profiles.

They are inevitably so structured that it is difficult to

decide the thicknes of the wood which can accommodate these

curved profiles.

One surest answer is this photo, two point contact with

L angled alminium piece. Any extra protrusion, or even

that inward can be easily measured, and that is

transcribed into the seperation between the table saw blade and

the fence that you are using.

Here below, a few long spoons at K's request.

Also at K's request I am working on these Chinese spoons,

version I.

These are the by-products of the Chinese spoons. I want

to ake the best use of them. How best? Mini spoons?

Salt spoons?

Nex two photos showing you my small one piece milk

pitcher. It took up a lot of my time. I will not sell it

for less than JPY 3500!

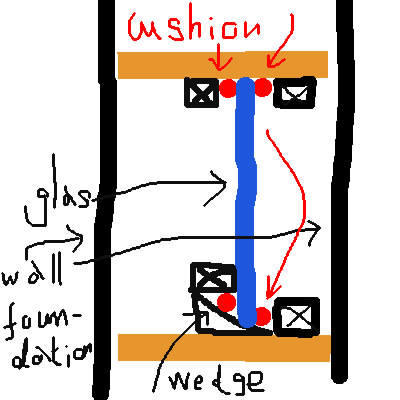

Here on, my mind drifting back to the house building.

OK, fixed windows are sold, but the trouble with them is

that they are supposed to be fixed in, disregarding the

possibility of window pane breakage.

If the window panes are smashed then you will have to

replace them. And, how you would do that is my problem.

Commercially available fixed window setting does not

take that into account at all!

Wedges at the bottom, polyethylene cushioning materials

all around might be the easiest solution. I will be using

other supporting materilas, but the idea is that these

glass panes must be detachable from the fixing rigs.

Naturally, bolting or screwing will be required.

If you come to think about it you could also have fixed

airing windows, yes?, and the openings can be easily

constructed for closure.

I have not gievn enough thought to this issue, but

the whole idea is attractive enough, I think...

the thickness of the material you want for this kind of side profiles.

They are inevitably so structured that it is difficult to

decide the thicknes of the wood which can accommodate these

curved profiles.

One surest answer is this photo, two point contact with

L angled alminium piece. Any extra protrusion, or even

that inward can be easily measured, and that is

transcribed into the seperation between the table saw blade and

the fence that you are using.

Here below, a few long spoons at K's request.

Also at K's request I am working on these Chinese spoons,

version I.

These are the by-products of the Chinese spoons. I want

to ake the best use of them. How best? Mini spoons?

Salt spoons?

Nex two photos showing you my small one piece milk

pitcher. It took up a lot of my time. I will not sell it

for less than JPY 3500!

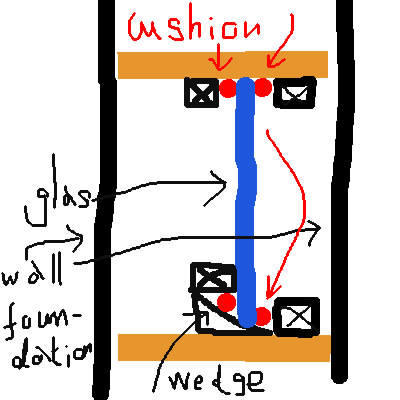

Here on, my mind drifting back to the house building.

OK, fixed windows are sold, but the trouble with them is

that they are supposed to be fixed in, disregarding the

possibility of window pane breakage.

If the window panes are smashed then you will have to

replace them. And, how you would do that is my problem.

Commercially available fixed window setting does not

take that into account at all!

Wedges at the bottom, polyethylene cushioning materials

all around might be the easiest solution. I will be using

other supporting materilas, but the idea is that these

glass panes must be detachable from the fixing rigs.

Naturally, bolting or screwing will be required.

If you come to think about it you could also have fixed

airing windows, yes?, and the openings can be easily

constructed for closure.

I have not gievn enough thought to this issue, but

the whole idea is attractive enough, I think...