Today, I think I will talk about chopstics making

at some length, but before that take a look at the

following image.

These are redundancies from my earlier work. I have

been wondering all this while how I might best make

use of them. What follows is the outcome.

Incidentally, I will show you how these redundancies

came about in the first place, with the first of

my illustrations for today.

Only 4 pairs of shorter chopstics! It is pretty much

obvious that I did not divert a lot of my attention

to my work! Cannot help it!, with games going on

all the time and my wife wanting to go shopping with

me. One outcome of that is the next image.

Rather simplistic way of getting myself a little

more comfortable, but it did wonder! I noticed

two things there.

First of all I was getting the breeze from behind.

That means that the dusts are blown away from me,

not depositing on my clothes and my arms.

Secondly, I was feeling very comfortable. I bought

a bucket, also, so that dusts covered arms of mine

can be dipped into water, for dusts removing and

generally lowering my body temperature, at least

partially...

I now have both! However, times spent on my

work will continute to be less than usual, due to

the games!

Now, let me start...

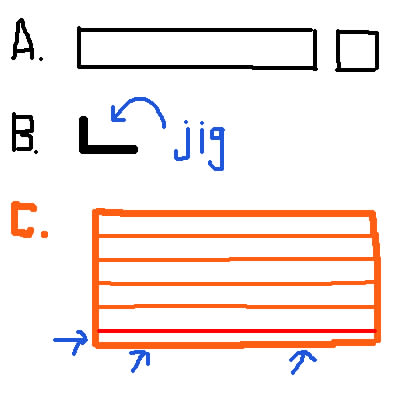

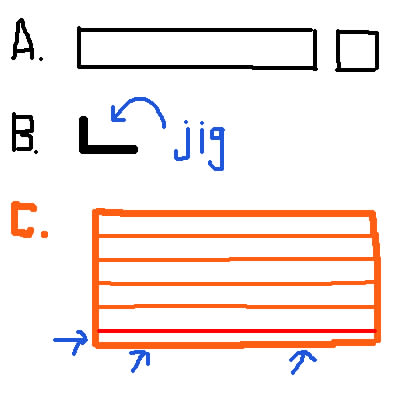

A. of this illustration is showing you the side view of

the chopstic to be, with its cross-section on the right.

It is a rectangular piece of bar, very simple.

B. is showing you the cross-section of my jig, made of

alminium, bought at a DIY nearby. You then set it against a piece

of a wooden block, one at a time, after one cutting process.

That is to say that once you have separated the first rectangular

piece from the block, you set the jig again and draw the

reference line with a pencil.

In the end you have several pieces of these rectangular bars

for forming them into chopstics. However, you are often left with

an odd-man-out, as indicated by the blue arrows.

This is how my redundant pieces came about, as shown in the

first photo of today. I am pleased that I did not throw them

away! They have been turned into chopstics!

Now, take a look at the next.

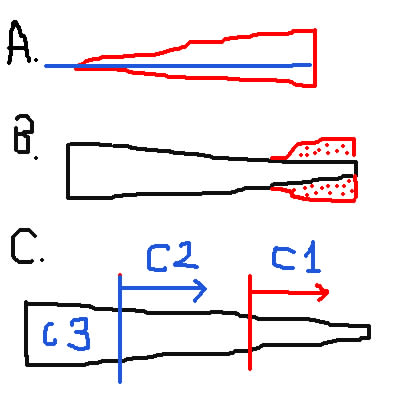

With this, A. is the schematic side view of my belt sander. In the middle is the flat bench, and on either side of it are the rollers

(in red) and the belt runs over the bed in the direction

indicated by the horizontal green arrow. You can also see

two gaps indicated by A and B. These are where problems

arise, particularly at the gap B.

In order to lose mas you need to press your work down

onto the flat bench, but at the gaps there is no effective

pressure exerted on the sanding belt.

In the end you end up with something like B. in

this illustration. Blue arrows indicate where

mas has been lost, and the red arrow shows the part

where not much mas has been lost. Remember that this is a schematic

and exageration is there...

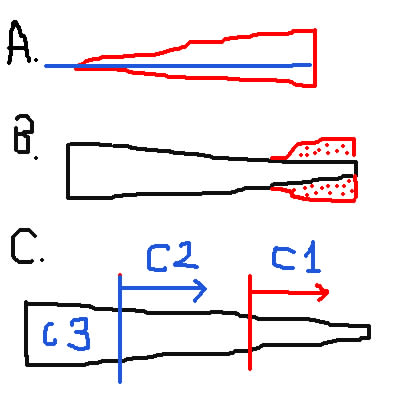

What this illustration is telling you is that I prepare the rough

shape of my chopstic to be by my disc sander. Initially, the

piece is made into a long rectangular wedge.

Then, about two thirds of the 4 edges are sanded out, making the

narrower end looking like octagonal in cross-section, with red parts

having been rounded.

At this stage of the game, the whole thing is still too fat,

too thick, and the surface covered by horrible scurs,

due to the angle of holding the piece against the disc...

Scurs go at angles to the normal grain direction!

What then you will have to do is pretty obvious. That is

to say you use your belt sander to lose further mas,

wanting a long rectangular and tapered piece of wood.

With the illustration above I no longer remember what I

was going to mention with A. Let us forget about this and

take a look at B.

In order to erase the scurs I always start with the thicker

ends, and because of the gap problem, you always end up

with the pointed ends (eventually..., that is) having

redundant mas, as indicated by the red dots. In reality,

it is ever so easy to remove them, by flipping over the

stick and sanding them out.

So, what do you have at this stage? Well, you have a much slimmer

piece of chopstic to be, well defined in all aspects, and without

scurs!

Having reached this stage, I refer you to the C. of the same

illustration. You have to further round the edges. I start with

the portion C1, and this portion will be round in the end

(cross-sectionally, that is).

Next comes the portion C2, press this portion against the

flat bed, fairly hard, so that its cross-section is neither

circular nor square, somewhere halfway between them.

If you do that the section C3's sharp edges are slightly

sanded automatiocally, and inevitably, but that is precisely what you want!

You want this section to be square in cross-section, but

not to the extent of its sharp edges hurting your hand!,

when you eventually hold your chopstics.

There are other minor details, but this is what my

chiopstics making process is all about!

at some length, but before that take a look at the

following image.

These are redundancies from my earlier work. I have

been wondering all this while how I might best make

use of them. What follows is the outcome.

Incidentally, I will show you how these redundancies

came about in the first place, with the first of

my illustrations for today.

Only 4 pairs of shorter chopstics! It is pretty much

obvious that I did not divert a lot of my attention

to my work! Cannot help it!, with games going on

all the time and my wife wanting to go shopping with

me. One outcome of that is the next image.

Rather simplistic way of getting myself a little

more comfortable, but it did wonder! I noticed

two things there.

First of all I was getting the breeze from behind.

That means that the dusts are blown away from me,

not depositing on my clothes and my arms.

Secondly, I was feeling very comfortable. I bought

a bucket, also, so that dusts covered arms of mine

can be dipped into water, for dusts removing and

generally lowering my body temperature, at least

partially...

I now have both! However, times spent on my

work will continute to be less than usual, due to

the games!

Now, let me start...

A. of this illustration is showing you the side view of

the chopstic to be, with its cross-section on the right.

It is a rectangular piece of bar, very simple.

B. is showing you the cross-section of my jig, made of

alminium, bought at a DIY nearby. You then set it against a piece

of a wooden block, one at a time, after one cutting process.

That is to say that once you have separated the first rectangular

piece from the block, you set the jig again and draw the

reference line with a pencil.

In the end you have several pieces of these rectangular bars

for forming them into chopstics. However, you are often left with

an odd-man-out, as indicated by the blue arrows.

This is how my redundant pieces came about, as shown in the

first photo of today. I am pleased that I did not throw them

away! They have been turned into chopstics!

Now, take a look at the next.

With this, A. is the schematic side view of my belt sander. In the middle is the flat bench, and on either side of it are the rollers

(in red) and the belt runs over the bed in the direction

indicated by the horizontal green arrow. You can also see

two gaps indicated by A and B. These are where problems

arise, particularly at the gap B.

In order to lose mas you need to press your work down

onto the flat bench, but at the gaps there is no effective

pressure exerted on the sanding belt.

In the end you end up with something like B. in

this illustration. Blue arrows indicate where

mas has been lost, and the red arrow shows the part

where not much mas has been lost. Remember that this is a schematic

and exageration is there...

What this illustration is telling you is that I prepare the rough

shape of my chopstic to be by my disc sander. Initially, the

piece is made into a long rectangular wedge.

Then, about two thirds of the 4 edges are sanded out, making the

narrower end looking like octagonal in cross-section, with red parts

having been rounded.

At this stage of the game, the whole thing is still too fat,

too thick, and the surface covered by horrible scurs,

due to the angle of holding the piece against the disc...

Scurs go at angles to the normal grain direction!

What then you will have to do is pretty obvious. That is

to say you use your belt sander to lose further mas,

wanting a long rectangular and tapered piece of wood.

With the illustration above I no longer remember what I

was going to mention with A. Let us forget about this and

take a look at B.

In order to erase the scurs I always start with the thicker

ends, and because of the gap problem, you always end up

with the pointed ends (eventually..., that is) having

redundant mas, as indicated by the red dots. In reality,

it is ever so easy to remove them, by flipping over the

stick and sanding them out.

So, what do you have at this stage? Well, you have a much slimmer

piece of chopstic to be, well defined in all aspects, and without

scurs!

Having reached this stage, I refer you to the C. of the same

illustration. You have to further round the edges. I start with

the portion C1, and this portion will be round in the end

(cross-sectionally, that is).

Next comes the portion C2, press this portion against the

flat bed, fairly hard, so that its cross-section is neither

circular nor square, somewhere halfway between them.

If you do that the section C3's sharp edges are slightly

sanded automatiocally, and inevitably, but that is precisely what you want!

You want this section to be square in cross-section, but

not to the extent of its sharp edges hurting your hand!,

when you eventually hold your chopstics.

There are other minor details, but this is what my

chiopstics making process is all about!