Most, if not all, of my time today was spent on

making extra nail beds. Obviously, I need a qauntity of nails

and the first thing to do was to drive to a 100 yen shop.

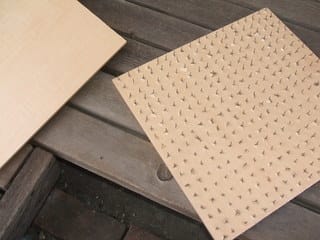

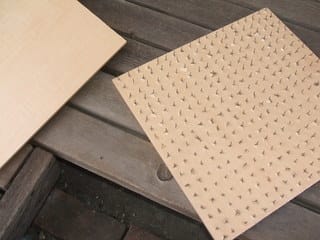

This is a low density bed (right) and I am

going to make three of these. It is my gut feeling

that I will be making more and more of large objects.

I do not need high density beds for them.

This is a high density bed. You can place small items

without wowrrying too much about the possibility of them

falling into the gaps. In fact, the density of this

particular bed is such that it took me a few days,

as I remember it...

Today, I ran out of drying space. What you are looking at,

Conchita, is a wire mesh. This made me think...

This wire mesh has a very large area. Yes, it is a wire net.

I thought of two things. One is that after all I may

not need nail beds for the first two penetration

coatings. This is primarily because during the first

two steps polyuretane will not emerge up to the

surface. That means my objects can safely rest

on the wire mesh. And, my second thought relates to that.

No nail beds for the first two steps, fine, but

after that I will still need my nail beds.

Polyurethane saturation after the thrid coating,

as in most cases, does require pointed supports.

That is why I decided to make more of the nail beds.

Quite apart from all this I always thought I could do with

extra nail beds. It is therefore high time that

I made them.

By large objects, I mean something like these above.

You can see that two of my infant feeders are

squeezed between giant objects.

I could place a lot of these small objects on the

same bed. That will make my life a lot easier.

The wire mesh, by the way, has another merit, if I come to

think about it. It is this. Penetration coating is such an

important stage in my coating and my objects

need an ample time for drying and post coating

processings, such as wet sanding and polyp removal.

Up until now my coating has been one of continous

operation. Surface buildup immediately after

the third of the penetration coating. With the

wire thing, I could treat a lot more of

my objects to the penetration than my nail beds

can cope with. That would be fine, because

what cannot go on to the nail bedding stage

they can wait and dry even longer. That suits me fine.

Above? Yes, I bought these at the same 100 yen shop.

The idea is this. They are all of broad leaves. That means

I can coat them, and even sell them?

Just take a look at the fourth picture of today, those

disk like objects. I did not make them. I just bought them

off the shelf for JPY 150 each.

They are also of broad leaves and I knew that I will be

ble to make them rise and shine from their obscure

origin.

Am I cheating? No, I don't think so. I am simply adding more

values. I, of course, stand to be challenged.

making extra nail beds. Obviously, I need a qauntity of nails

and the first thing to do was to drive to a 100 yen shop.

This is a low density bed (right) and I am

going to make three of these. It is my gut feeling

that I will be making more and more of large objects.

I do not need high density beds for them.

This is a high density bed. You can place small items

without wowrrying too much about the possibility of them

falling into the gaps. In fact, the density of this

particular bed is such that it took me a few days,

as I remember it...

Today, I ran out of drying space. What you are looking at,

Conchita, is a wire mesh. This made me think...

This wire mesh has a very large area. Yes, it is a wire net.

I thought of two things. One is that after all I may

not need nail beds for the first two penetration

coatings. This is primarily because during the first

two steps polyuretane will not emerge up to the

surface. That means my objects can safely rest

on the wire mesh. And, my second thought relates to that.

No nail beds for the first two steps, fine, but

after that I will still need my nail beds.

Polyurethane saturation after the thrid coating,

as in most cases, does require pointed supports.

That is why I decided to make more of the nail beds.

Quite apart from all this I always thought I could do with

extra nail beds. It is therefore high time that

I made them.

By large objects, I mean something like these above.

You can see that two of my infant feeders are

squeezed between giant objects.

I could place a lot of these small objects on the

same bed. That will make my life a lot easier.

The wire mesh, by the way, has another merit, if I come to

think about it. It is this. Penetration coating is such an

important stage in my coating and my objects

need an ample time for drying and post coating

processings, such as wet sanding and polyp removal.

Up until now my coating has been one of continous

operation. Surface buildup immediately after

the third of the penetration coating. With the

wire thing, I could treat a lot more of

my objects to the penetration than my nail beds

can cope with. That would be fine, because

what cannot go on to the nail bedding stage

they can wait and dry even longer. That suits me fine.

Above? Yes, I bought these at the same 100 yen shop.

The idea is this. They are all of broad leaves. That means

I can coat them, and even sell them?

Just take a look at the fourth picture of today, those

disk like objects. I did not make them. I just bought them

off the shelf for JPY 150 each.

They are also of broad leaves and I knew that I will be

ble to make them rise and shine from their obscure

origin.

Am I cheating? No, I don't think so. I am simply adding more

values. I, of course, stand to be challenged.