Today, I did not do anything in terms of new cutlery pieces.

The day started with wet sanding and drying and coating again,

taking up so much of my time...

On top of that my daughter went back to the very north, and

I took her to the station. As my son is in the very south,

they are both students, they will be apart over the

distance of some 4,000 km, again! What a crazy family we actually are!

Making use of the rest of the afternoon, I started working

on calligraphy brushes stand for my wife. All of the brushes

have a small ring on the end and that prompted me to make

use of one of the redundant peices, which was an wedge, in its

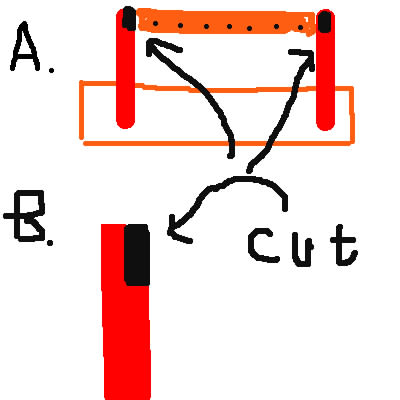

original state. I saw it down the length of it with my

bandsaw. Take a look.

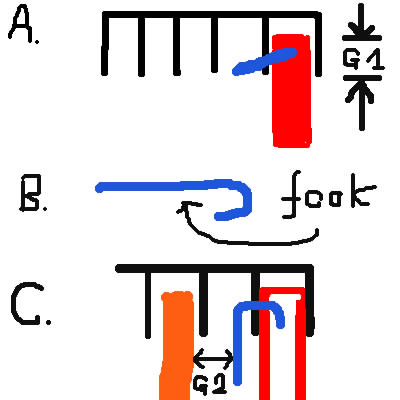

You can see that a long stick is pointing upward, and that

is exactly what you want to hang things on it. What follows

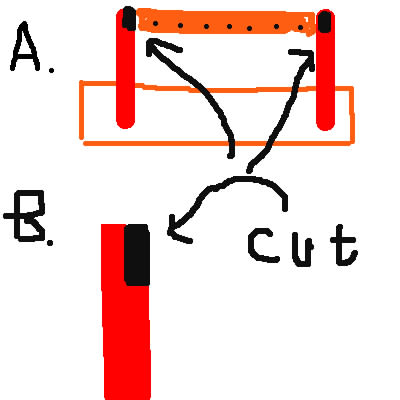

is a schematic.

Look at C and D, and with the above photo the stick is

perpendiular to the surface. How do you ensure that?

As in C, you make a cut, paralell to the side on the

left, and flip over the separated wedge underneath

the main block.

Put together, they form a flat piece, with parallell

surface both above and bellow, and that is exactly

what you need to make your holes perpendicular to the

upper surface! Clever, is it not? Green bars indicate

the pegs.

What follows shows you the result.

Can you see that the two pieces forming what you want, and the

stick (or the peg to be) pointing upward?

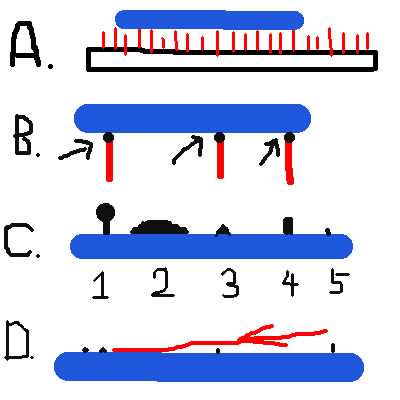

Now, what might be the grand scheme? Obviously, you do not

want to spend hours and hours on a simple artefact like this.

On the other hand making each member strictly vertical and

horizontal is a must. Take a look at the following illustration.

By far the easiest way to errect a vertical supporting

structure is to make use of a round piece of rod, and you make

a hole with sufficient depth, and you just stick it in!

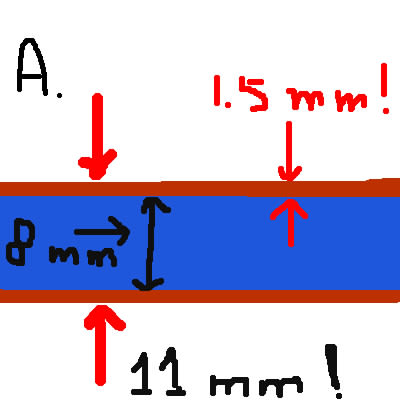

Next image shows you the base block, with enough mas, and

sitting a top is the bit that I will be using tommorrow

for hole making.

You may say that the base block is too bulky? Who cares!

You need to support up to 8 soaky brushes with the

supporting pillars.

It is my gut-feeling that you need something like this

to support the super-structure...

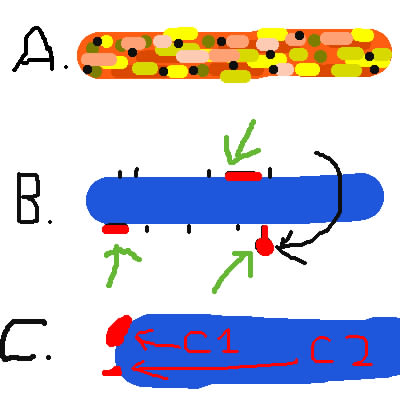

What about the pillars? See bellow.

You obviously need a step with each piller, and above shows that

my milling machine has done the job. The horizontal bar with

8 or 9 pegs will be placed on these steps and glued!

I might even use a few reinforcing screws...

Anyway, that is the lot for today...

The day started with wet sanding and drying and coating again,

taking up so much of my time...

On top of that my daughter went back to the very north, and

I took her to the station. As my son is in the very south,

they are both students, they will be apart over the

distance of some 4,000 km, again! What a crazy family we actually are!

Making use of the rest of the afternoon, I started working

on calligraphy brushes stand for my wife. All of the brushes

have a small ring on the end and that prompted me to make

use of one of the redundant peices, which was an wedge, in its

original state. I saw it down the length of it with my

bandsaw. Take a look.

You can see that a long stick is pointing upward, and that

is exactly what you want to hang things on it. What follows

is a schematic.

Look at C and D, and with the above photo the stick is

perpendiular to the surface. How do you ensure that?

As in C, you make a cut, paralell to the side on the

left, and flip over the separated wedge underneath

the main block.

Put together, they form a flat piece, with parallell

surface both above and bellow, and that is exactly

what you need to make your holes perpendicular to the

upper surface! Clever, is it not? Green bars indicate

the pegs.

What follows shows you the result.

Can you see that the two pieces forming what you want, and the

stick (or the peg to be) pointing upward?

Now, what might be the grand scheme? Obviously, you do not

want to spend hours and hours on a simple artefact like this.

On the other hand making each member strictly vertical and

horizontal is a must. Take a look at the following illustration.

By far the easiest way to errect a vertical supporting

structure is to make use of a round piece of rod, and you make

a hole with sufficient depth, and you just stick it in!

Next image shows you the base block, with enough mas, and

sitting a top is the bit that I will be using tommorrow

for hole making.

You may say that the base block is too bulky? Who cares!

You need to support up to 8 soaky brushes with the

supporting pillars.

It is my gut-feeling that you need something like this

to support the super-structure...

What about the pillars? See bellow.

You obviously need a step with each piller, and above shows that

my milling machine has done the job. The horizontal bar with

8 or 9 pegs will be placed on these steps and glued!

I might even use a few reinforcing screws...

Anyway, that is the lot for today...