Today was good, good for coating, which

still continues, of course.

With my wife away, somewhere up in Tochigi,

I had to busy myself with things, and what

I achieved was not very much.

However, there was a new insight into containrs

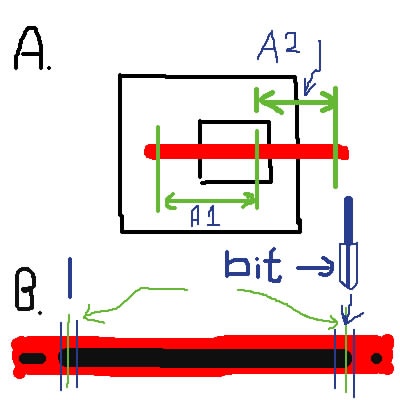

fabrication, that is, trench making. Take a look at the

overall picture with the following illustration.

With A, the larger square is my cross-table, and

the smaller square is my vice, fixed on the cross-table.

The red bar is my workpiece, in which a trench is

to be made. Because this is a milling machine, my cross-

table can move about, in X-, and in Y-, directions.

However, the distances that can be covered are limited.

A1 is the maximum horizontal shift I can make. That is

to say that the trench making must be done in two parts.

A2 is the remaining second pass I can make.

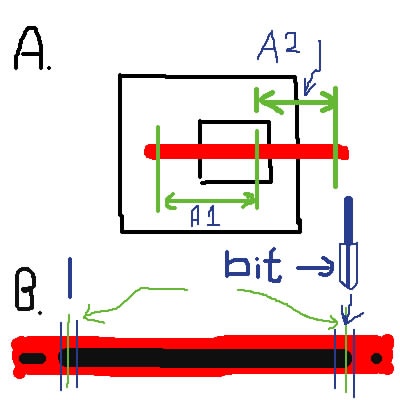

Today's discovery is this. When you have reached the very

end of the first run, you must relax on your vice grip

so that your uncompleted workpiece can move sideways,

between the gripping elements. At this stage, however,

I have reached the end of the 1st pass, so moving the

workpiece and positioning the bit over the reference line

means automatically that you will not overshoot at the

2nd pass. If you overshoot, you will obliterrate the

space where the locking hole is to be made.

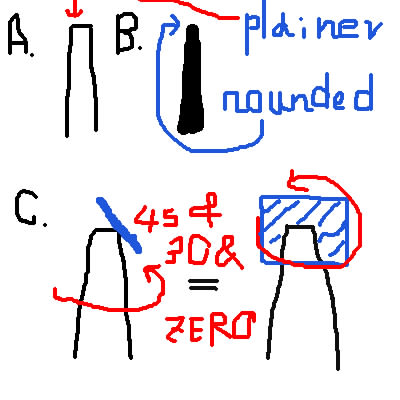

Take a look at the side profile of the bit. Not

exactly perfect, but there is a line feature, there,

which may be taken as the centre (or dividing) line of the

bit diameter.

Why am I making a fuss about all this? The primary

reason is the dusts during operation. The whole thing

is a messy business, with dusts flying away in profusion,

making it very difficult to view these reference lines...

These reference lines, for trench making are shown as the green

lines with B. What you then do is to allign the centre of

the bit to the green line and get going.

What follows is showing you my output for the day.

Three more containers, more or less, completed, except

rounding the edges. It is my triumph that I have identified

procedural elements in trench making...

I am also praising myself over the precision of

the trenches. Shifting your workpiece can easily

lead to discontinuities, where the shifting takes place.

In reality, there is no recognizable discontinuity.

If there were that could be obliterated easily with my

rugby ball sander!

still continues, of course.

With my wife away, somewhere up in Tochigi,

I had to busy myself with things, and what

I achieved was not very much.

However, there was a new insight into containrs

fabrication, that is, trench making. Take a look at the

overall picture with the following illustration.

With A, the larger square is my cross-table, and

the smaller square is my vice, fixed on the cross-table.

The red bar is my workpiece, in which a trench is

to be made. Because this is a milling machine, my cross-

table can move about, in X-, and in Y-, directions.

However, the distances that can be covered are limited.

A1 is the maximum horizontal shift I can make. That is

to say that the trench making must be done in two parts.

A2 is the remaining second pass I can make.

Today's discovery is this. When you have reached the very

end of the first run, you must relax on your vice grip

so that your uncompleted workpiece can move sideways,

between the gripping elements. At this stage, however,

I have reached the end of the 1st pass, so moving the

workpiece and positioning the bit over the reference line

means automatically that you will not overshoot at the

2nd pass. If you overshoot, you will obliterrate the

space where the locking hole is to be made.

Take a look at the side profile of the bit. Not

exactly perfect, but there is a line feature, there,

which may be taken as the centre (or dividing) line of the

bit diameter.

Why am I making a fuss about all this? The primary

reason is the dusts during operation. The whole thing

is a messy business, with dusts flying away in profusion,

making it very difficult to view these reference lines...

These reference lines, for trench making are shown as the green

lines with B. What you then do is to allign the centre of

the bit to the green line and get going.

What follows is showing you my output for the day.

Three more containers, more or less, completed, except

rounding the edges. It is my triumph that I have identified

procedural elements in trench making...

I am also praising myself over the precision of

the trenches. Shifting your workpiece can easily

lead to discontinuities, where the shifting takes place.

In reality, there is no recognizable discontinuity.

If there were that could be obliterated easily with my

rugby ball sander!