Today, I made a smallish (or biggish?) discovery.

I will talk more about that later.

It rained on and off today, so I spent all of my time

working on Chinese spoons etc. Caoting continued,

no photo of that.

Below, you see a group of coating ready Chinese spoons.

I never expected that I would be able to bring them

all to this stage today.

All this is thanks to the discovery, perhaps long

overdue... Anyway, that meant that I could work on

these cornflake spoons as well.

Here below, I even had time to make one of them coating ready.

However, all this is actually dwarfed by today's discovery.

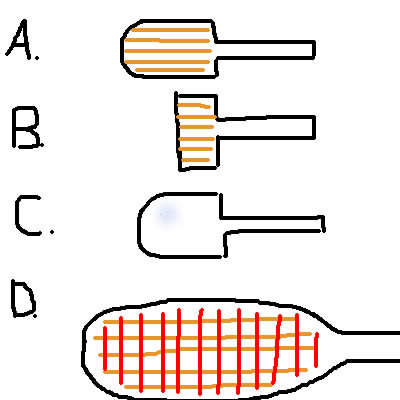

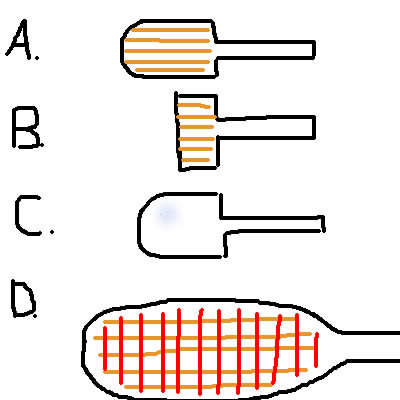

I will talk about it with the following schematics.

As with anything else it is not that time comsuming

to get one piece of my work coating ready. However,

if you have more than 10, say, your work slows down.

With concave surfaces, I have always used two abrasive flappers

as shown as A and B above. Net result of these sanding

operations is that, as shown with the last schematic,

there are light scurrs across the grain, which are shown

in red against the background of grain direction (brown).

It is not that difficult and time consuming to remove these

light scurrs by hand sanding. Natutrally, at this stage of

hand sanding you need to attend to the rest of the piece.

So, I guess that each takes up 7, or 8 minutes, including

peripherals and the rear convex surface, plus the stem

end.

However, 70% of that time is actually taken up

by concave sanding by hand. You are almost led to

this hand sanding procedure, after two sessions

of machine sanding. After all, before then the

concave surface would look wildly rough. So, once

machine sanding is done you think naively that

the rest can be managed by hand... Well, yes, but...

no...

Today's discovery is the schematic C. It is a snading bit,

but not a flapper. It is solid like sponge, at the

grain rating of 180. Initially, I was skeptical.

However, it does a wonder! Those red scurrs can be removed

in, I should imagne, 30 seconds!

It makes me think, and it really does that all of my

operation is built up on these small dayily discoveries.

I have come a long way... and I am almost like

a real artisan, am I not? How long has all this taken?

4 years? Yes, something like that...

Here I am, surrounded by an assortment of machines

and sanding bits and jigs I have made I am able to

produce a range of pieces...

Is it not an achievement? Where do I go from here...?

I will talk more about that later.

It rained on and off today, so I spent all of my time

working on Chinese spoons etc. Caoting continued,

no photo of that.

Below, you see a group of coating ready Chinese spoons.

I never expected that I would be able to bring them

all to this stage today.

All this is thanks to the discovery, perhaps long

overdue... Anyway, that meant that I could work on

these cornflake spoons as well.

Here below, I even had time to make one of them coating ready.

However, all this is actually dwarfed by today's discovery.

I will talk about it with the following schematics.

As with anything else it is not that time comsuming

to get one piece of my work coating ready. However,

if you have more than 10, say, your work slows down.

With concave surfaces, I have always used two abrasive flappers

as shown as A and B above. Net result of these sanding

operations is that, as shown with the last schematic,

there are light scurrs across the grain, which are shown

in red against the background of grain direction (brown).

It is not that difficult and time consuming to remove these

light scurrs by hand sanding. Natutrally, at this stage of

hand sanding you need to attend to the rest of the piece.

So, I guess that each takes up 7, or 8 minutes, including

peripherals and the rear convex surface, plus the stem

end.

However, 70% of that time is actually taken up

by concave sanding by hand. You are almost led to

this hand sanding procedure, after two sessions

of machine sanding. After all, before then the

concave surface would look wildly rough. So, once

machine sanding is done you think naively that

the rest can be managed by hand... Well, yes, but...

no...

Today's discovery is the schematic C. It is a snading bit,

but not a flapper. It is solid like sponge, at the

grain rating of 180. Initially, I was skeptical.

However, it does a wonder! Those red scurrs can be removed

in, I should imagne, 30 seconds!

It makes me think, and it really does that all of my

operation is built up on these small dayily discoveries.

I have come a long way... and I am almost like

a real artisan, am I not? How long has all this taken?

4 years? Yes, something like that...

Here I am, surrounded by an assortment of machines

and sanding bits and jigs I have made I am able to

produce a range of pieces...

Is it not an achievement? Where do I go from here...?