Conchita, this image just below is showing you the

extra materials I got from a furnitur factory.

They are all dark walnut. In fact, the president of the

company asked me to represnt his company with my pieces

at a department store in the region. I had to comply

with his request. It may turn out be THE occasion...

Here above, my decision with the spheres is that

I will turn them into salt and pepper things. See

the nut and bolt? I will use them for sealing the

bottom of the enclosure. I will cut the tube into

slices and use each for bonding the nut, with the whole

assembly in turn bonded to the bottom of the sphere.

The white thing is a 60 mm hole saw I bought years ago

for cutting out metal discs up to 5mm thick. I need

this hole saw in order to make a jig for holding

the spheres with my vise while making a large diamtre

hole down the centre of spheres.

Here above, this is my attmept to fabricate dinosour

butter knives, looking like pandas. Do I call them

panda dinosours? Anyway, the idea here is that unlike

previous dinosour butter knives there will be a sharper

contrast, just like my earlier killer whale things...

Here, this is an initial experiment with birch side

bands. I am not too sure about their dry relative

density. You only need to experiment to find out

thebalancing effects!

Some more of the spheres I bought today, just indicating

my seriousness!

Here above, completed brush hangers. These will be

taken to shops for sale immediately. Price tag?

It will be up to the shop owners, but I will be

insisting on a minimum of JPY 2750. I know that similar

jigs are sold for over JPY 5000.

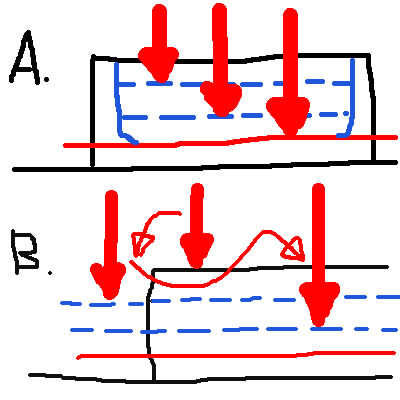

Going back to the salt and pepper things I will be

carrying a schematic about the design, tommorrow?

Ideally, I need a decicating something solid to go inside

the bore. Powder things are not ideal...

Mind you, commercially available counterparts

do not have such a mechanism! Only mine!

extra materials I got from a furnitur factory.

They are all dark walnut. In fact, the president of the

company asked me to represnt his company with my pieces

at a department store in the region. I had to comply

with his request. It may turn out be THE occasion...

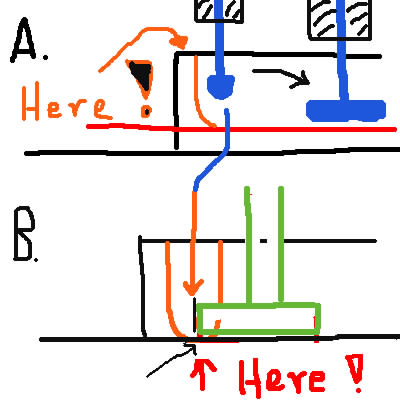

Here above, my decision with the spheres is that

I will turn them into salt and pepper things. See

the nut and bolt? I will use them for sealing the

bottom of the enclosure. I will cut the tube into

slices and use each for bonding the nut, with the whole

assembly in turn bonded to the bottom of the sphere.

The white thing is a 60 mm hole saw I bought years ago

for cutting out metal discs up to 5mm thick. I need

this hole saw in order to make a jig for holding

the spheres with my vise while making a large diamtre

hole down the centre of spheres.

Here above, this is my attmept to fabricate dinosour

butter knives, looking like pandas. Do I call them

panda dinosours? Anyway, the idea here is that unlike

previous dinosour butter knives there will be a sharper

contrast, just like my earlier killer whale things...

Here, this is an initial experiment with birch side

bands. I am not too sure about their dry relative

density. You only need to experiment to find out

thebalancing effects!

Some more of the spheres I bought today, just indicating

my seriousness!

Here above, completed brush hangers. These will be

taken to shops for sale immediately. Price tag?

It will be up to the shop owners, but I will be

insisting on a minimum of JPY 2750. I know that similar

jigs are sold for over JPY 5000.

Going back to the salt and pepper things I will be

carrying a schematic about the design, tommorrow?

Ideally, I need a decicating something solid to go inside

the bore. Powder things are not ideal...

Mind you, commercially available counterparts

do not have such a mechanism! Only mine!