It has been a hard day..., with the heat and all the rest of it...

Coating of the saucers continues. And, the brush

hanger parts are OK, as shown bellow.

This afternoon started with the cutting out plate

springs with my very expensive bandsaw for metal cutting.

Originally purchased for my loom work, but it is

rarely used these days. The bandsaw is shown bellow.

This is a very versatile machine, and in theory

this allows me to cut soft iron, brass, let alone

aluminum alloys of up to something like 10 cm thickness...

Today, I was using it for a mere thickness of 2 mm...

Other related jobs?

Making holes right in the centre of the plates is

paramount to my grooves. My vice cannot properly

grip these 6 mm wide plates, and even if gripped

the pressure of the drill bit will vend it. So,

I need an underlying support, such as a piece of

wood, gripped by the vice.

My milling machine has an accuracy down to one tenth

of a millimeter, so making holes with the 6 mm wide

plates is not that difficult...

Outcome is shown bellow.

Here, I am being sick of myself, again...

The hole positions are all worng! See those

standing and you will see what I am talking about.

It looks as if I will have to live with these

unsatistactory 8 plate springs for my learing works...

Anyway, take a look at what follows.

They are not yet assembled, but the basic idea is there.

In all this, what crossed my mind was that those on

the right may be even better. After all, you do not want to

use huge tongs, really...

Oh, here, by the way, you can see better the hole positions

I was talking about above. Anyway, while working with

all these, another idea came to my mind.

See bellow.

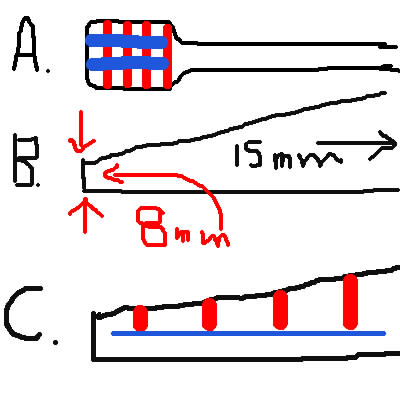

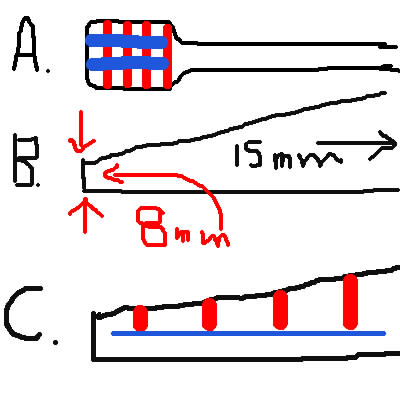

With the schematic A, the red bars are the grooves, and

the blue bars are the slits. My idea was that instead of

having a flat and closed plate like grappers, I may even

use fork like grappers for my tongs. I tried out this idea

and what you see bellow is the outcome.

As you can see one of the pokers broke off! This is

a designing issue, and I will have to think further

about this fiasco...

Additionally, I will have to clear the issues

schematised as B and C. Do I really want a constant

depth of these grooves?

Should I not start with squarely flat pieces,

so that I do not need to worry about the constant

depth issue?

I am in a deep thinking mode...

Coating of the saucers continues. And, the brush

hanger parts are OK, as shown bellow.

This afternoon started with the cutting out plate

springs with my very expensive bandsaw for metal cutting.

Originally purchased for my loom work, but it is

rarely used these days. The bandsaw is shown bellow.

This is a very versatile machine, and in theory

this allows me to cut soft iron, brass, let alone

aluminum alloys of up to something like 10 cm thickness...

Today, I was using it for a mere thickness of 2 mm...

Other related jobs?

Making holes right in the centre of the plates is

paramount to my grooves. My vice cannot properly

grip these 6 mm wide plates, and even if gripped

the pressure of the drill bit will vend it. So,

I need an underlying support, such as a piece of

wood, gripped by the vice.

My milling machine has an accuracy down to one tenth

of a millimeter, so making holes with the 6 mm wide

plates is not that difficult...

Outcome is shown bellow.

Here, I am being sick of myself, again...

The hole positions are all worng! See those

standing and you will see what I am talking about.

It looks as if I will have to live with these

unsatistactory 8 plate springs for my learing works...

Anyway, take a look at what follows.

They are not yet assembled, but the basic idea is there.

In all this, what crossed my mind was that those on

the right may be even better. After all, you do not want to

use huge tongs, really...

Oh, here, by the way, you can see better the hole positions

I was talking about above. Anyway, while working with

all these, another idea came to my mind.

See bellow.

With the schematic A, the red bars are the grooves, and

the blue bars are the slits. My idea was that instead of

having a flat and closed plate like grappers, I may even

use fork like grappers for my tongs. I tried out this idea

and what you see bellow is the outcome.

As you can see one of the pokers broke off! This is

a designing issue, and I will have to think further

about this fiasco...

Additionally, I will have to clear the issues

schematised as B and C. Do I really want a constant

depth of these grooves?

Should I not start with squarely flat pieces,

so that I do not need to worry about the constant

depth issue?

I am in a deep thinking mode...