Today, I decided to go mat with the current lot. See below.

There are some more, still remaining in my shed for drying overnight.

I am quite satisfied with these results. They look lovely...

Some of these will be shipped within the next few days,

to K's shop, in particular.

Seen above are the spacers for the next lot of portable

bootsholders. They look simple enough, but they take a lot of time.

For a start you have to have the right thickness and

that means cutting with the bandsaw to 6 mm, then sanding down

to 5 mm.

Here above, I now have a complete set of chopstics

to be, all 13 pairs of them! 3 of them wilbe retained here

for domestic use and the rest will be given away as gifts.

As seen above, I also made provision for further 14

bootsholders. Right now, I have another 6 in the pipeline, and

10 of them will be shipped, and the remaining 10 will be

given away as gifts. Anyway, all these above are routine

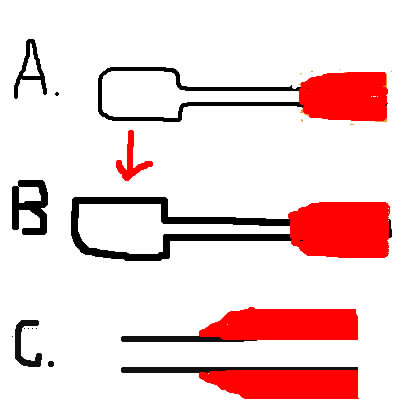

jobs, as it were. Today's main conceren was what is shown

below, a new type of butter knives...

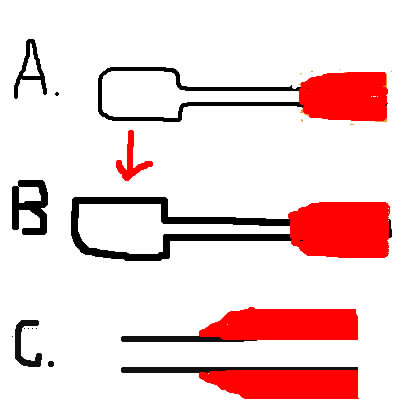

This schematic has been put into reality, as shown below.

The centre piece is oak, to be sandwiched by 2 pieces of

dark walnut. This is just experimental, so I only made one.

One on the right is a template. Mind you, I have not yet

firmly decided on the design. So much so, the centre piece

is not smoothe at all.

The main reason is the discontinuity at the sandwiched

portion of the stem. It is awfully difficult to sand down

the dark walnut pieces only.

Even if you can do it, no, you cannot possiblely do that!,

My expectation is that I will be sanding down the walnuts,

but also the oak piece as well, so that somooth curvature

is obtained. More on that tommorrow with schematics.

There are some more, still remaining in my shed for drying overnight.

I am quite satisfied with these results. They look lovely...

Some of these will be shipped within the next few days,

to K's shop, in particular.

Seen above are the spacers for the next lot of portable

bootsholders. They look simple enough, but they take a lot of time.

For a start you have to have the right thickness and

that means cutting with the bandsaw to 6 mm, then sanding down

to 5 mm.

Here above, I now have a complete set of chopstics

to be, all 13 pairs of them! 3 of them wilbe retained here

for domestic use and the rest will be given away as gifts.

As seen above, I also made provision for further 14

bootsholders. Right now, I have another 6 in the pipeline, and

10 of them will be shipped, and the remaining 10 will be

given away as gifts. Anyway, all these above are routine

jobs, as it were. Today's main conceren was what is shown

below, a new type of butter knives...

This schematic has been put into reality, as shown below.

The centre piece is oak, to be sandwiched by 2 pieces of

dark walnut. This is just experimental, so I only made one.

One on the right is a template. Mind you, I have not yet

firmly decided on the design. So much so, the centre piece

is not smoothe at all.

The main reason is the discontinuity at the sandwiched

portion of the stem. It is awfully difficult to sand down

the dark walnut pieces only.

Even if you can do it, no, you cannot possiblely do that!,

My expectation is that I will be sanding down the walnuts,

but also the oak piece as well, so that somooth curvature

is obtained. More on that tommorrow with schematics.